- Joined

- Jan 8, 2016

- Messages

- 171

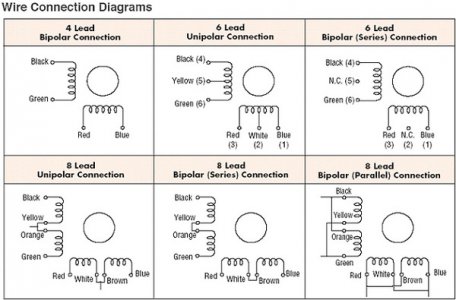

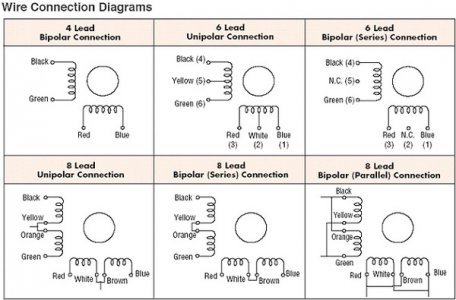

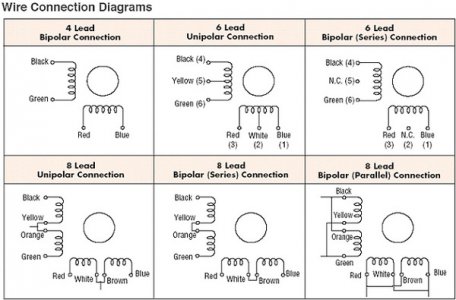

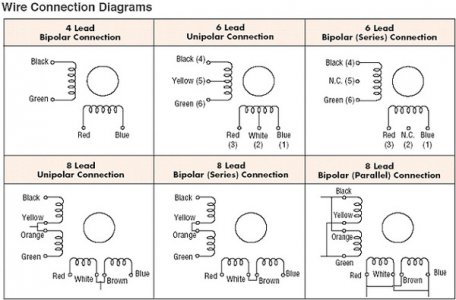

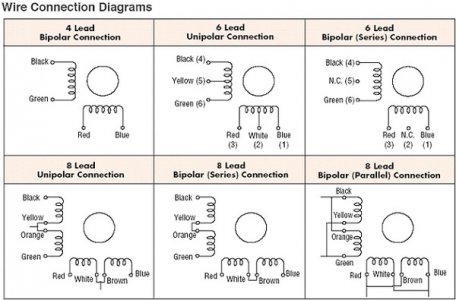

Looking at motor specs, most just say 2 phase and give a torque rating. Some however, such as this

http://www.omc-stepperonline.com/ne...per-motor-31nm439-ozin-24hs343008d-p-275.html have 8 wires and can be configured however you want.

I take it most motors are bipolar parallel? I understand the difference, just don't know what is standard when it is not stated.

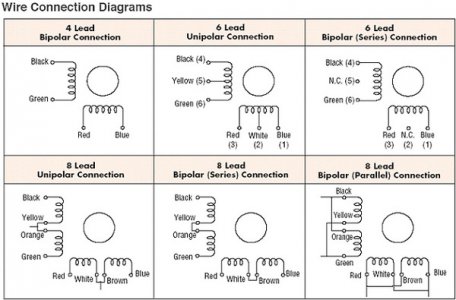

Rated Current(Bipolar Serial) 2.1A

Rated Current(Bipolar Parallel) 4.2A

http://www.omc-stepperonline.com/ne...per-motor-31nm439-ozin-24hs343008d-p-275.html have 8 wires and can be configured however you want.

I take it most motors are bipolar parallel? I understand the difference, just don't know what is standard when it is not stated.

Rated Current(Bipolar Serial) 2.1A

Rated Current(Bipolar Parallel) 4.2A