Hi folks,

I posted this message on another forum I frequent, but I figured it may be useful to people here.

I got a lot of help from Rich King and also from Forest over on HSM, when I first set out on making these tools I'd never touched a scraper, but now I'm confident I can do what I need quite quickly and easily.

I made an 18" straight parallel, a 14" master square, a 9" dovetail tool, and scraped/modified a 24" knife edge camelback. The parallel and the square are both accurate to about half a division on my 0.002mm indicator, ie to about half a tenth.

Here's some pics of the end result plus some pics of the process below:

Also made this nice plywood box for them, box took almost as long as the tools:

Couldn't resist stamping my name on the steel plate, the big straight edge just hangs and doesn't touch the carpet:

All this started by using a massive angle grinder to chop up this 70kg 18" x 12" x 12" milling cube I got off eBay for £30. Shows how long ago it was, that's snow on the ground:

Then I had to start machining the resultant lumps up:

Bit of blue paint, may as well try to hide the Dykem which will end up all over them:

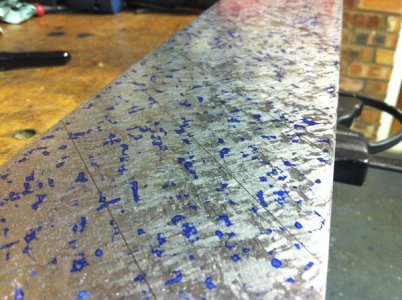

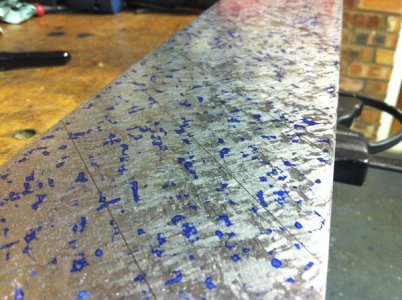

And thus began the scraping process...

After some months I managed to snag a Biax for less then a mortgage payment, so the process sped up. The parallel and the small wedge I did by hand, but the square and the straight edge with the biax:

Now, the straight edge I bought off a bloke and it was 36" long. My surface plate is only 24". After realising the straight edge wasn't flat and needed a thorough rescrape, I took the decision to cut it down to 24":

The edges were filled with body filler and sanded smooth, this meant I could then spot the thing properly and got it rescraped to a high level.

The square is first scraped with both sides exactly parallel, then using an indicator you can figure out how vertical it sits, and rescrape the base to tilt it back or forth. In so far as my technique allows, I appear to have the square within about 0.001mm square between an inch or so from the bottom and top, which I was truly chuffed with.

Was almost disappointed when I used the master square to check my existing cheap ground square... and found it was dead on Almost needn't have bothered making it!

Almost needn't have bothered making it!

And here's a small video of the straight edge as it was nearing completion:

http://www.youtube.com/watch?v=P5HrNqG1fv4&feature=youtu.be

Glad it's over with! Now I just need to use them to rescrape all 3 of my machines... Well actually, you may notice I haven't yet scraped the knife edge on the camelback.

Rich

I posted this message on another forum I frequent, but I figured it may be useful to people here.

I got a lot of help from Rich King and also from Forest over on HSM, when I first set out on making these tools I'd never touched a scraper, but now I'm confident I can do what I need quite quickly and easily.

I made an 18" straight parallel, a 14" master square, a 9" dovetail tool, and scraped/modified a 24" knife edge camelback. The parallel and the square are both accurate to about half a division on my 0.002mm indicator, ie to about half a tenth.

Here's some pics of the end result plus some pics of the process below:

Also made this nice plywood box for them, box took almost as long as the tools:

Couldn't resist stamping my name on the steel plate, the big straight edge just hangs and doesn't touch the carpet:

All this started by using a massive angle grinder to chop up this 70kg 18" x 12" x 12" milling cube I got off eBay for £30. Shows how long ago it was, that's snow on the ground:

Then I had to start machining the resultant lumps up:

Bit of blue paint, may as well try to hide the Dykem which will end up all over them:

And thus began the scraping process...

After some months I managed to snag a Biax for less then a mortgage payment, so the process sped up. The parallel and the small wedge I did by hand, but the square and the straight edge with the biax:

Now, the straight edge I bought off a bloke and it was 36" long. My surface plate is only 24". After realising the straight edge wasn't flat and needed a thorough rescrape, I took the decision to cut it down to 24":

The edges were filled with body filler and sanded smooth, this meant I could then spot the thing properly and got it rescraped to a high level.

The square is first scraped with both sides exactly parallel, then using an indicator you can figure out how vertical it sits, and rescrape the base to tilt it back or forth. In so far as my technique allows, I appear to have the square within about 0.001mm square between an inch or so from the bottom and top, which I was truly chuffed with.

Was almost disappointed when I used the master square to check my existing cheap ground square... and found it was dead on

And here's a small video of the straight edge as it was nearing completion:

http://www.youtube.com/watch?v=P5HrNqG1fv4&feature=youtu.be

Glad it's over with! Now I just need to use them to rescrape all 3 of my machines... Well actually, you may notice I haven't yet scraped the knife edge on the camelback.

Rich