- Joined

- Nov 8, 2011

- Messages

- 1,678

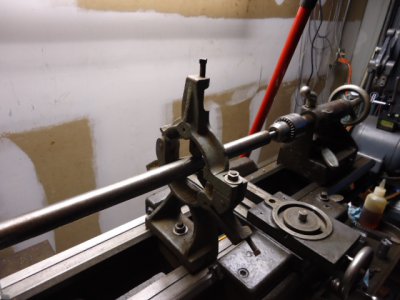

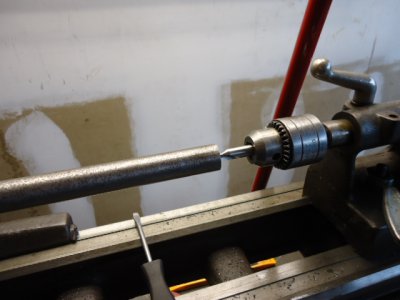

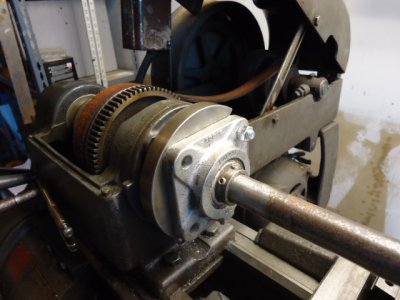

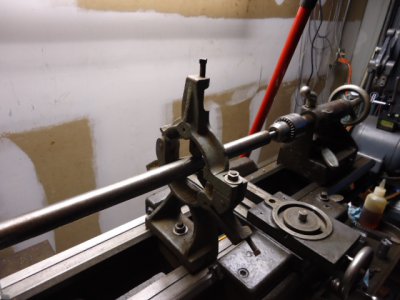

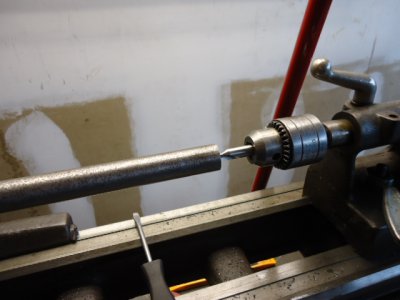

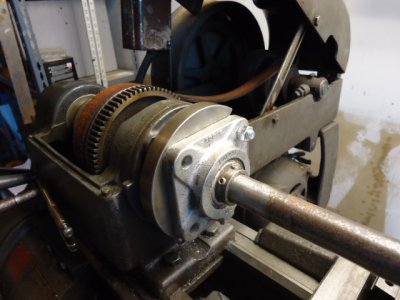

I needed to turn a shaft for the drive pulley on my Burke mill, I wanted to do it between centers so I dig out my face plate and dog but cannot find a center for it plus the dog would not fit over the stock. I have never used a setup like this or even seen it used but had asked a question about setting it up and found out I needed a center.

With my lack of patients and my bullheadedness I was determined to make some chips and fix my Burke. The stock I had for the job had a taper turned on one end so took advantage of that rigged up this contraption & it worked out well. The pictures tell it all, Video to follow.

With my lack of patients and my bullheadedness I was determined to make some chips and fix my Burke. The stock I had for the job had a taper turned on one end so took advantage of that rigged up this contraption & it worked out well. The pictures tell it all, Video to follow.