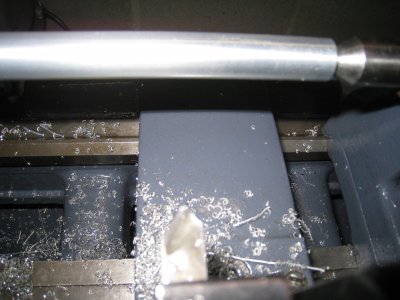

Thanks to Toag and others for steering me to HSS instead of carbide. I spent about 1 hour today grinding my first tool, R.H. turning. There really is a lot of science behind all these angles. Much to my surprise when I tried it out - IT Worked!! Actually left a better finish on my alum. practice piece than my carbide insert. I have a long way to go but it's always nice to get a positive result the first time out. Back to the books and videos.

Jack C.

Jack C.