- Joined

- Dec 18, 2019

- Messages

- 6,464

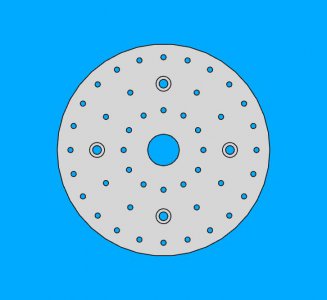

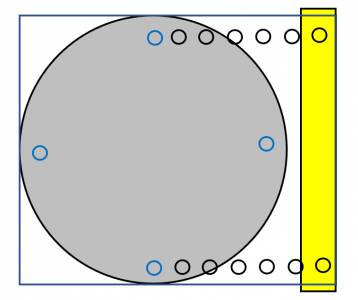

Planning to make a fixture plate for my HV-6 rotary table. What is the most useful hole pattern? Square array? Polar? Something else? I am starting to draw it up.

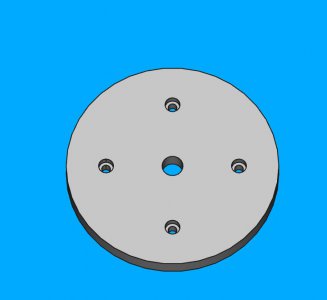

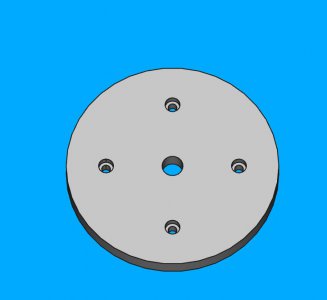

For reference, I have a 6" table. An 8" plate will fit. Plate will be 3/4" thick aluminum. Will have a locating hole in the center. (Will machine an MT2 soft arbor.) Is there a hole pattern that you found useful, or no matter what one does, the holes are never in the right place! M8 mounting holes shown in picture below - match the tee-nuts I just made.

Should the tapped holes be blind?

For reference, I have a 6" table. An 8" plate will fit. Plate will be 3/4" thick aluminum. Will have a locating hole in the center. (Will machine an MT2 soft arbor.) Is there a hole pattern that you found useful, or no matter what one does, the holes are never in the right place! M8 mounting holes shown in picture below - match the tee-nuts I just made.

Should the tapped holes be blind?