- Joined

- Sep 5, 2013

- Messages

- 3,208

You are correct, the Supermatic (I have three) does use a cleated cord belt as well although they employ the more common wire style of cleat. Here’s a picture of one hiding just behind the cam…I Believe that they use the same type of belt, not sure that they would fit.

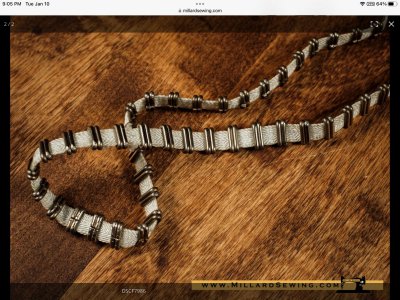

I don’t know about the spacing and it may be quite close although there’s also the problem of hitting exactly the right belt length too — there is no adjustment room. I have seen wire cleated belts that use two and sometimes three wire cleats side-by-side (my Singer 306, for example) to obtain a wider cleat and that option did cross my mind as well. I just ended up showing more promise with the flat aluminum material over my wire experiments so I went with it. This is double-cleat cord belt for a Pfaff…

The original Turissa belts were very contemporary in appearance — they look just like a synchronous belt you’d buy today — just that the pitch seems to not be common anymore. As for the material they were made from though, that’s an interesting question given how they seem to self-destruct after 60 years or so. That said, I have seen an original Turissa belt of the cord style too, so it looks like there were a couple variations possibly depending on the year. Here’s a couple photos of original Turissa belts still in place as well as another NOS replacement one that is supposedly available for purchase in Finland. It’s worth noting that one of the co-founders behind the Turissa was Fritz Gegauf of Bernina reputation. You can see a lot of similarities to Bernina as well as Elna in the Turissa.

One last photo — this is the belt from the 1950’s IBM typewriter I scrapped a while ago. It fit the Turissa pulley perfectly but was about an inch too small in diameter. Dang!

-frank