I am "spring-cleaning" the apron and saddle of my 1947 South Bend 9A.

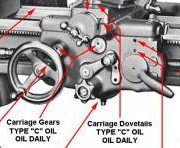

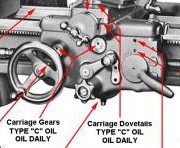

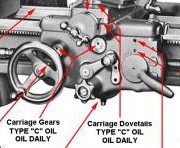

After 10 hours of research I find many references to the oiling of the usual SB 9A points marked in yellow below:

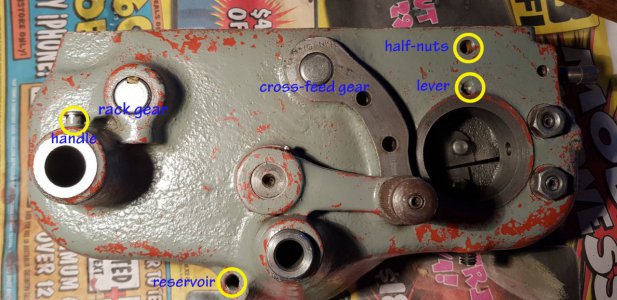

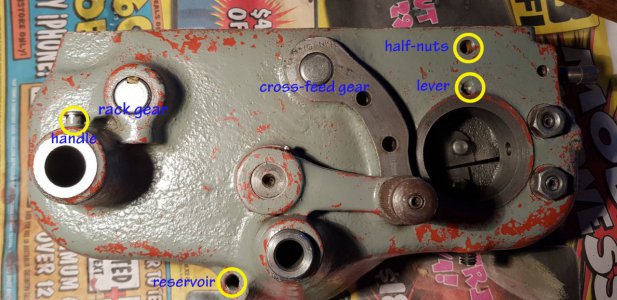

However, lubrication of the gears for the rack and the power cross-feed are rarely, if ever mentioned.

From the top view (below) you can see that both of the gear shafts have felt wicks for oil.

How does oil get to the wicks ?

The slot on the rack gear shaft (on my lathe) DOES open to the front face, so it could be lubricated by attempting to squirt oil directly into the end of the wick.

If this is an oil-point, I don't recall it being mentioned , it is easily missed, and it would be messy to use because it has no cup or recess. Nevertheless, this small fuzzy chart does seem to show it (behind the handwheel, top right)

On my lathe, lubrication of the power cross-feed gear is even more mysterious since the slot for the oil wick stops before it reaches the front face of the apron. This means that oiling must occur from the back (which would not be possible without removing the saddle from the apron). Unlike the lubrication diagram shown above, my lathe has no hole in the end of the shaft.

Does oil "raineth from the heavens above" from the spindle of the cross-feed assembly somehow ?

Or, should I rotate the shaft so that the slot is at the bottom, and drill a diagonal hole (or two holes at right-angles) from the end face of the shaft to meet up with the oil slot ? Why would my lathe not have this hole ?

What arrangement do you folks have on your SB 9A lathes ? Any thoughts from anyone ?

After 10 hours of research I find many references to the oiling of the usual SB 9A points marked in yellow below:

However, lubrication of the gears for the rack and the power cross-feed are rarely, if ever mentioned.

From the top view (below) you can see that both of the gear shafts have felt wicks for oil.

How does oil get to the wicks ?

The slot on the rack gear shaft (on my lathe) DOES open to the front face, so it could be lubricated by attempting to squirt oil directly into the end of the wick.

If this is an oil-point, I don't recall it being mentioned , it is easily missed, and it would be messy to use because it has no cup or recess. Nevertheless, this small fuzzy chart does seem to show it (behind the handwheel, top right)

On my lathe, lubrication of the power cross-feed gear is even more mysterious since the slot for the oil wick stops before it reaches the front face of the apron. This means that oiling must occur from the back (which would not be possible without removing the saddle from the apron). Unlike the lubrication diagram shown above, my lathe has no hole in the end of the shaft.

Does oil "raineth from the heavens above" from the spindle of the cross-feed assembly somehow ?

Or, should I rotate the shaft so that the slot is at the bottom, and drill a diagonal hole (or two holes at right-angles) from the end face of the shaft to meet up with the oil slot ? Why would my lathe not have this hole ?

What arrangement do you folks have on your SB 9A lathes ? Any thoughts from anyone ?