This may take me a while to explain, but I promise that it will eventually arrive at a discussion of machining...or how little I know about machining...or how I can make every project much more complicated and expensive than necessary.

This is my 1954 Willys CJ-3B

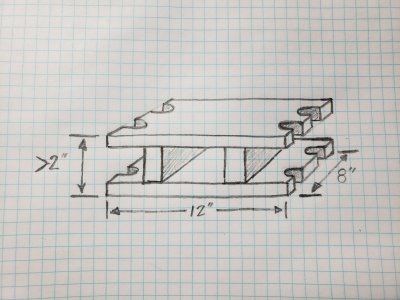

I like to spend my free time tinkering, rebuilding, or otherwise modifying it to suit my tastes. Most recently, I decided to replace the tattered front bumper with a design of my own.

This is my 1954 Willys CJ-3B

I like to spend my free time tinkering, rebuilding, or otherwise modifying it to suit my tastes. Most recently, I decided to replace the tattered front bumper with a design of my own.