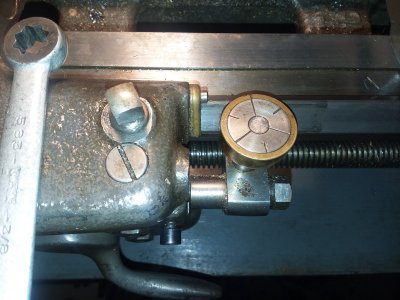

In my work to rejuvenate a Logan 825, I've gotten to the threading dial. I cleaned it up a while back with the rest of the lathe in my other thread, but I just installed and had a closer look at it. I have been impressed with the detail and complexity that went into the design of this lathe overall, but the threading dial looks like they had the blind and drunk apprentice on night shift make it. When the half nuts are engaged, the mark on the body does not line up with anything on the dial. You sort of have to guess the timing. I've also never seen a dial with the opposing numbers like this. Knowing that a PO of my lathe had made some other "modifications" is this really the original dial? Has anyone made a new one? Post pictures of your threading dials please!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Logan Threading Dial

- Thread starter bhusted

- Start date

- Joined

- Sep 24, 2020

- Messages

- 1,917

I'll probably try making a new face for the dial. This one must come off somehow if the PO was able to make one.

I've never seen a threading dial with an odd number of marks like that. Does the SB have an 8TPI leadscrew? How would that work? I guess you really only need 1 mark as long as you always engage on that one.

I've never seen a threading dial with an odd number of marks like that. Does the SB have an 8TPI leadscrew? How would that work? I guess you really only need 1 mark as long as you always engage on that one.

- Joined

- Sep 24, 2020

- Messages

- 1,917

Yes, my leadscrew is 8 TPI.I'll probably try making a new face for the dial. This one must come off somehow if the PO was able to make one.

I've never seen a threading dial with an odd number of marks like that. Does the SB have an 8TPI leadscrew? How would that work? I guess you really only need 1 mark as long as you always engage on that one.

- Joined

- Oct 18, 2016

- Messages

- 2,872

That dial is not a Logan part.

Mine came with a non-standard dial as well, but it was blank. I recently marked the dial by indexing the spindle

on the lathe and scribing the lines. The dial itself is an easy part to turn, though there is a tiny hole at the bottom

for the roll pin that secures the gear that would have to be drilled carefully.

Mine came with a non-standard dial as well, but it was blank. I recently marked the dial by indexing the spindle

on the lathe and scribing the lines. The dial itself is an easy part to turn, though there is a tiny hole at the bottom

for the roll pin that secures the gear that would have to be drilled carefully.

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,516

On the threading dial and its markings, most of the time you really could live with only one mark. If you are not in a hurry. Exception would be for multi-start threads.

Since you can't physically make a fraction of a thread, it might not be doable, but how fast the threading dial rotates depends upon the lead screw pitch and the number of teeth in the actual threading gear.

Since you can't physically make a fraction of a thread, it might not be doable, but how fast the threading dial rotates depends upon the lead screw pitch and the number of teeth in the actual threading gear.

That dial is not a Logan part.

Mine came with a non-standard dial as well, but it was blank. I recently marked the dial by indexing the spindle

on the lathe and scribing the lines. The dial itself is an easy part to turn, though there is a tiny hole at the bottom

for the roll pin that secures the gear that would have to be drilled carefully.

Thanks! I like the look of your dial. Does the face not just separate from the shaft? I've been hesitant to disassemble mine as it sort of "works". Did you take any pictures of yours when you had it apart?

With regard to multi start threads, I actually just did some of that today. I understand that one could do it using the threading dial, but I prefer to swing the compound parallel to the bed and cut the other starts by advancing the compound.

- Joined

- Oct 18, 2016

- Messages

- 2,872

On mine, the head and shaft are a single part. Sorry, no pictures, but the shaft portion is simply a straight, uniform diameter with

the larger diameter face. Easy turning job. Of course, you could make it up as a 2 piece assembly, but I'm not sure that would

be less trouble.

the larger diameter face. Easy turning job. Of course, you could make it up as a 2 piece assembly, but I'm not sure that would

be less trouble.