-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Logan backgear shifting difficult

- Thread starter Jack C.

- Start date

I'm new to the forum & metalworking. I recently bought a Logan/wards 10" lathe and an cleaning & painting it. The backgear is very hard to shift. I did read and try Scott Logans advice about removing and re-installing the shift rod but the gears aren't moving like they should. When I do get the gears meshed it works good. I was trying to avoid pulling the headstock off so I thought maybe you guys had some ideas. Thanks for your help.

Jack C.

jack,

I am a newbie with this too, I think I had a similar problem. I had to learn on my own, try to pull and unlock the pin to unlock the forward gears. essentially putting it in neutral. this pin is located on the side of the gear nearest to the your chuck.

and or be sure to clean all gears you can find, then of coarse re-lubricate them. I have found a lot of information about these things on Utube.

what color are you painting it?

hope this helps

good luck with your project !

Dennis

Hmmmm....

I'm not seeing what you are referring to here in terms of its usefulness? I assume you mean while synchronizing the shifter? I did mine only a couple of weeks ago, and my feeble brain has already dumped what I learned then. I don't want to miss out on any neat tricks! As I recall, once I had the teeth meshed, and was happy with the lash, I simply locked the collar with about 1/16" free gap from when the latch key popped into lock position.

I had to go back down to the basement last night and refresh said feeble brain on how it all worked before I posted at all. As I had recalled, the only issue for me in getting back gears engaged is whether the gear teeth are meshing. If they are it slips right in. If not, a little turn of the spindle finds a mesh point quickly. I suppose it bears mentioning that you never want to do ANYTHING with the back gears while the lathe is running. Given the sorry state my lathe was in (mine HAD no shifter, etc), I wonder how many times someone shifted it on the fly?

Then again, that is probably an obvious answer.... ONCE!

You don't want to try to shift your lathe in or out of back gear with the spindle is rotating.

I used to engage the back gear to remove chucks that screwed on. I placed a piece of plywood on the ways in case I dropped the chuck. It is normal for a lathe when in back gear to rattle some compared to straight drive. Make sure to either oil or use a little grease on the gear teeth. Bringing back some fond memories.

jack,

I am a newbie with this too, I think I had a similar problem. I had to learn on my own, try to pull and unlock the pin to unlock the forward gears. essentially putting it in neutral. this pin is located on the side of the gear nearest to the your chuck.

and or be sure to clean all gears you can find, then of coarse re-lubricate them. I have found a lot of information about these things on Utube.

what color are you painting it?

hope this helps

good luck with your project !

Dennis

Thanks Dennis. Gear shifts fine now that I got all the gunk removed. I am using Benjamin Moore oil base industrial enamel. The color is "Baby Seal Black" #2119-30. Someone had posted this info and the color matches perfect with some of the hidden areas that still had intact paint. I'll post some pics when I get everything finished.

Jack C.

- Joined

- Jul 27, 2013

- Messages

- 295

Hey;

I wish that BM offered a hardener for this stuff. I was tempted to use some from a different manufacturer - how much different can the chemistry be? - but let it slide. It dries REALLY SLOWLY, and not all that hard. Not very solvent resistant, at least in the short term. Who knows how hard it will get.... some day.

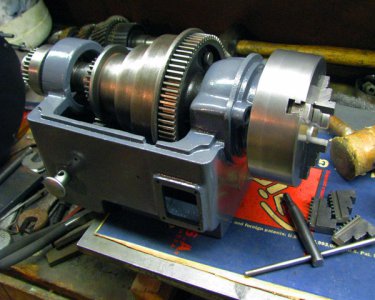

For reference, I've seen original lathes that ranged from a pale grey blue to almost black. Environment seems to have played a large role in what this soft old paint ended up looking like decades on. Here are some views of my color documentation efforts;

From under the nameplate.

Tops of the legs.

Benjamin Moore color chip.

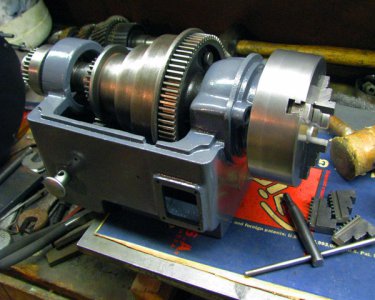

My refurbed headstock. Slightly lighter than it looks in the chip, and pretty close to original. Very complex and handsome color, I think.

I wish that BM offered a hardener for this stuff. I was tempted to use some from a different manufacturer - how much different can the chemistry be? - but let it slide. It dries REALLY SLOWLY, and not all that hard. Not very solvent resistant, at least in the short term. Who knows how hard it will get.... some day.

For reference, I've seen original lathes that ranged from a pale grey blue to almost black. Environment seems to have played a large role in what this soft old paint ended up looking like decades on. Here are some views of my color documentation efforts;

From under the nameplate.

Tops of the legs.

Benjamin Moore color chip.

My refurbed headstock. Slightly lighter than it looks in the chip, and pretty close to original. Very complex and handsome color, I think.

That's a nice looking color. I'm with you on the slow drying time for the BM paint. I used their urethane alkyd on an 11" Logan a couple of years ago. I had to let the parts sit for a couple of weeks before I reassembled it. Even then, it was still soft. It does harden up eventually. I just use the rustoleum now and brush it on. If I was going to spray another one, I would use the benny moore, it lays out really nice.