- Joined

- Jun 7, 2016

- Messages

- 361

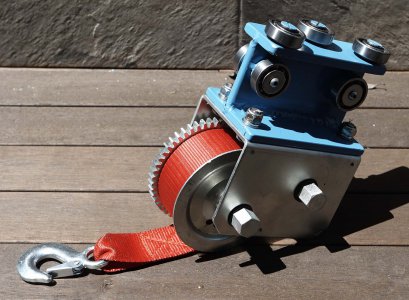

What a great set up.Best and smartest thing I did was run a low cost Unistrut trolley in my shop. The struts and trolleys are cheap. Just a couple of days work to hang the struts. Sorry for the so-so pics

I am sure you are making some great stuff in that workshop.

I particularly like the use of your doors as handing space.

Mal