- Joined

- Oct 12, 2021

- Messages

- 45

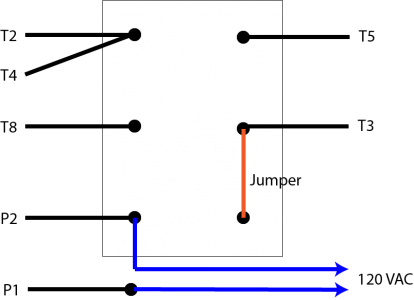

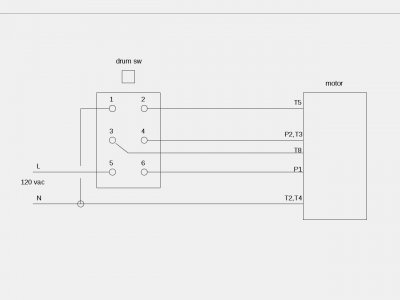

I just purchased a 1940s(?) South Bend heavy 10. The previous owner's son cut the wires (grrrr....) from the motor to the reversing drum switch to remove the lathe from the bench. Unfortunately, the wires were all red and unmarked (as seen in drum switch photo). I have attached a photo of the motor's faceplate. I can't find how to rewire this motor. All the posts I've seen have diagrams of wires P2-T3-T8 but I'm pretty sure T8 was not tied to P2-T3. I'm hesitant to hook it up as I don't want to burn anything up. Also, the wiring diagrams all have L1 and L2 but I assume this is P1 and P2 in my case. This was wired by the previous owner (deceased) for 120V and I would like to do the same.

I plan on replacing the power cable with a 12 gauge but 14 or 12 gauge from the switch to the motor? Thanks!

On a side note, what is "TAPE" on the motor faceplate? Tape the wires together?

On edit: I am assuming the Leland is an aftermarket motor?

Thanks.

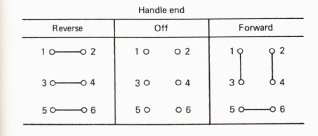

EDIT: Added this diagram of my reversing switch. I don't have the cover so I'm not sure whose it is. I'll be replacing it as the forward contacts are pretty well worn.

I plan on replacing the power cable with a 12 gauge but 14 or 12 gauge from the switch to the motor? Thanks!

On a side note, what is "TAPE" on the motor faceplate? Tape the wires together?

On edit: I am assuming the Leland is an aftermarket motor?

Thanks.

EDIT: Added this diagram of my reversing switch. I don't have the cover so I'm not sure whose it is. I'll be replacing it as the forward contacts are pretty well worn.

Last edited: