-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lead Screw backlash adjusting tool- DIY

- Thread starter Janderso

- Start date

- Joined

- Mar 26, 2018

- Messages

- 8,410

Looks like 16 TPIThanks so much!

Thanks to Jeff I was able to make this and successfully adjusted my (ahem) nuts.

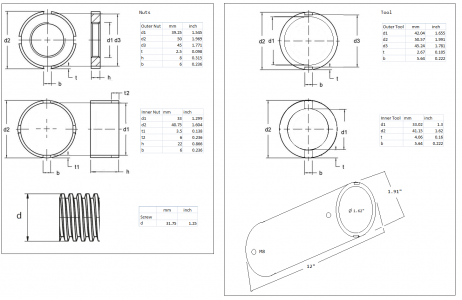

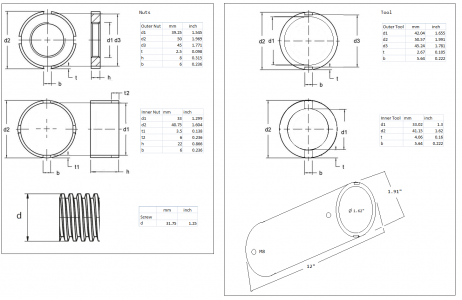

I had a 1 foot piece of 1.5" galvanized pipe, and although welding would be quicker, there is some fume danger** there and it was raining outside. So with Jeff's measurements I popped open Fusion 360...wait I am a hobby guy, I don't have fancy stuff like that! I mean I popped open paint, excel and the snipping tool and got to work! It occurred to me that I should measure it in metric too because the the numbers are dead on in a lot of cases. I used the lathe and the mill to make the end caps but it all could be done on the mill. I like to use my angle grinder handle on shop made tools when it makes sense, just drill and tap M8 thread and instant handle!

It occurred to me that I should measure it in metric too because the the numbers are dead on in a lot of cases. I used the lathe and the mill to make the end caps but it all could be done on the mill. I like to use my angle grinder handle on shop made tools when it makes sense, just drill and tap M8 thread and instant handle!

**Also PSA, Don't ever weld something after using chlorinated brake cleaner, it can create phosgene gas which will seriously maim or kill you!

I had a 1 foot piece of 1.5" galvanized pipe, and although welding would be quicker, there is some fume danger** there and it was raining outside. So with Jeff's measurements I popped open Fusion 360...wait I am a hobby guy, I don't have fancy stuff like that! I mean I popped open paint, excel and the snipping tool and got to work!

**Also PSA, Don't ever weld something after using chlorinated brake cleaner, it can create phosgene gas which will seriously maim or kill you!

- Joined

- Aug 6, 2015

- Messages

- 3,894

Bookmarked. I need to adjust the backslash on mine. Need to see if it is similar procedure for my Wells-Index.

Had an issue where the machine pulled the part and ruined it. I know, pilot error, but it showed me than the table slides more that necessary…

Had an issue where the machine pulled the part and ruined it. I know, pilot error, but it showed me than the table slides more that necessary…

Last edited:

Need to use backlash eliminator when climb milling. HTHBookmarked. I need to adjust the backslash on mine. Need to see if it is similar procedure for my Wells-Index.

Had an issue where the machine pulled the part and ruined it. I know, pilot error, but it showed me that the table slides more that necessary…

- Joined

- Aug 6, 2015

- Messages

- 3,894

That is why mentioned being user error... but I need to validate if the nut or screw (or both) have excessive wear... it just slides too much. I will document findings in my ownership thread.Need to use backlash eliminator when climb milling. HTH