- Joined

- Jan 28, 2022

- Messages

- 66

so I just got my second lathe its a little benchtop wood lathe, its about 5X bigger then my starting lathe (a tiny unimat SL)

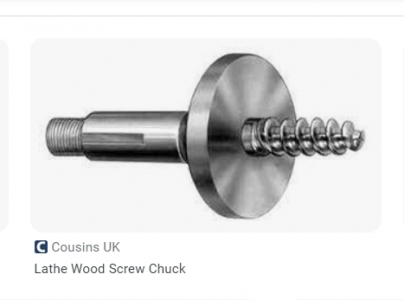

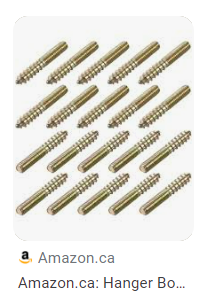

do to limited way to hold the projects, I've had to get creative on things, so on smaller things I have been using one of these (in a jacobs chuck)

as I had like 3 spares

a dremel polishing wheel holder has been used for small odds and ends

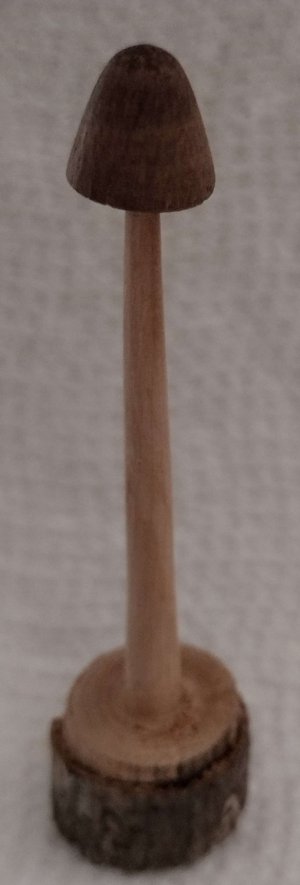

like the head of this mushroom , or the top part of this tree

, or the top part of this tree

this has worked pretty well and good, however today just testing out a new gouge 2 of my spares of these bent and are unusable now

so now the main ? on this, is there a product out there made out of a stronger metal for this already? would it be worth it to fire up the

little unimat and try to make it as its mostly just a small screw bit with a flat shelf for the wood to rest against

or is this one of those things thats so stupid in wood turning that its a shock I have not hurt myself yet?

do to limited way to hold the projects, I've had to get creative on things, so on smaller things I have been using one of these (in a jacobs chuck)

as I had like 3 spares

a dremel polishing wheel holder has been used for small odds and ends

like the head of this mushroom

, or the top part of this tree

, or the top part of this tree

this has worked pretty well and good, however today just testing out a new gouge 2 of my spares of these bent and are unusable now

so now the main ? on this, is there a product out there made out of a stronger metal for this already? would it be worth it to fire up the

little unimat and try to make it as its mostly just a small screw bit with a flat shelf for the wood to rest against

or is this one of those things thats so stupid in wood turning that its a shock I have not hurt myself yet?