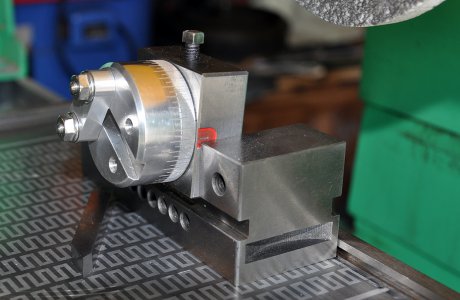

I had a little time in the shop so I started my version of the grinding fixture. I made it from whatever material I found in the scrap bin. The steel base is surface ground on all sides and I graduated the aluminum cylinder with 360 lines. I still need to make a clamp and add threaded clamp holes.

View attachment 106432

Matt

Great improvement. I like the graduations. This would be great to use on the belt sander to touch up tools and especially to sharpen the tangential tool bit.