- Joined

- Jun 2, 2015

- Messages

- 21

I just managed to complete another small project in my ongoing quest to add functionality to my lathe.

I hope this posting might inspire someone else to have a go, to improve or modify to their liking. Much in the same way this forum have inspired, or solved many of my own predicaments.

Let me first make clear that 10 months ago I had never used a lathe for anything, nor did I own one.

I have always been a builder/maker/tinker/woodworker, and have had a desire to delve into the machinist’s field, but I never got round to it. 10 months ago I decided to give myself an early birthday present in the form of a lathe. Here the story begins

Motivation:

I do not own a mill, and occasionally I use the lathe for indexing. To get around the issue of the workpiece rotating, I needed a reliable way of keeping the chuck locked. This is where a chuck brake would normally be used. However my lathe doesn’t have any, nor can I prevent the spindle rotation in any other way. My late is a generic 10x22 Chinese import. It just happens to bear the Weiss brand name, but it’s nearly identical to various other brands (Grizzly, Warco and PM). The described brake design could be applied directly to any of these if anyone fancies.

Design & considerations:

The main aim is to ensure no spindle movement while performing other machining operations. It is not meant to assist in stopping the chuck while rotating.

While researching and evaluating what had been done before, I came to the conclusion that I wanted to apply the braking power to the spindle itself.

With such an approach I could avoid any slack, slop or backlash in connected components. It was imperative not to put any load on the spindle bearings while braking was active.

I also wanted a system that should be fixed on the lathe at all times, and did not interfere with normal lathe work. Lastly it should be cheap and very functional, as I haven’t recently sold any valuable multibillion IT company.

As It is beyond my current skill level to machine an entire brake system, I needed to find usable components more or less off the shelf. I ended up adopting components from a bicycle diskbrake system.

If such a system can stop a 100kg gorilla going 40 km/h downhill on a bicycle, it should be able to hold a 5” chuck. Admittedly the use of bike parts was partly inspired by CrisB257 on youtube, but I did not want to copy the design completely.

Solution

With the specifications done, the remaining task was to find somewhere to place a brakedisk. This actually took quite some time to figure out, but now it seems simple enough.

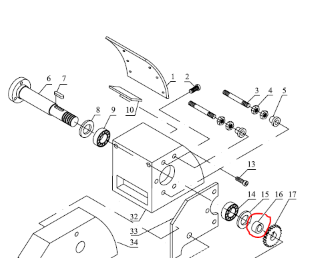

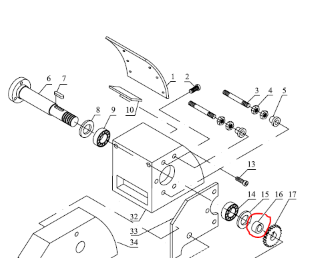

On the back of the spindle after the drive pulley is a gear, (part of the leadscrew gearing) after this, a few spacer bushings. I figured that it would be possible to remake the largest spacer, to include brakedisk.

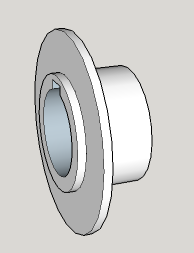

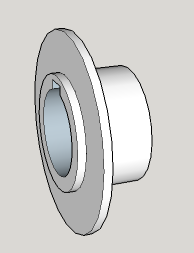

The new brakedisk spacer should look something like this

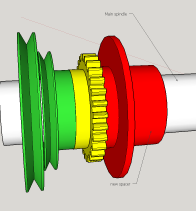

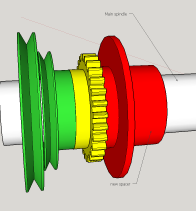

And this is how it assembles on the spindle.

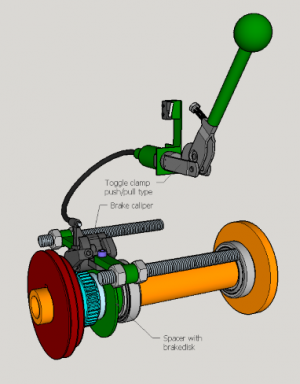

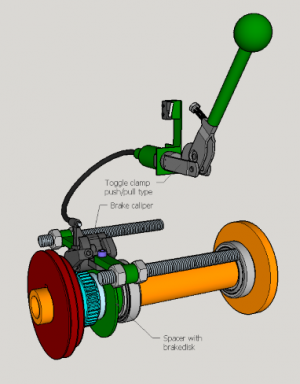

Next picture show an overview of the complete design: Green designates parts that need fabrication.

Topic will continue in next post.

I hope this posting might inspire someone else to have a go, to improve or modify to their liking. Much in the same way this forum have inspired, or solved many of my own predicaments.

Let me first make clear that 10 months ago I had never used a lathe for anything, nor did I own one.

I have always been a builder/maker/tinker/woodworker, and have had a desire to delve into the machinist’s field, but I never got round to it. 10 months ago I decided to give myself an early birthday present in the form of a lathe. Here the story begins

Motivation:

I do not own a mill, and occasionally I use the lathe for indexing. To get around the issue of the workpiece rotating, I needed a reliable way of keeping the chuck locked. This is where a chuck brake would normally be used. However my lathe doesn’t have any, nor can I prevent the spindle rotation in any other way. My late is a generic 10x22 Chinese import. It just happens to bear the Weiss brand name, but it’s nearly identical to various other brands (Grizzly, Warco and PM). The described brake design could be applied directly to any of these if anyone fancies.

Design & considerations:

The main aim is to ensure no spindle movement while performing other machining operations. It is not meant to assist in stopping the chuck while rotating.

While researching and evaluating what had been done before, I came to the conclusion that I wanted to apply the braking power to the spindle itself.

With such an approach I could avoid any slack, slop or backlash in connected components. It was imperative not to put any load on the spindle bearings while braking was active.

I also wanted a system that should be fixed on the lathe at all times, and did not interfere with normal lathe work. Lastly it should be cheap and very functional, as I haven’t recently sold any valuable multibillion IT company.

As It is beyond my current skill level to machine an entire brake system, I needed to find usable components more or less off the shelf. I ended up adopting components from a bicycle diskbrake system.

If such a system can stop a 100kg gorilla going 40 km/h downhill on a bicycle, it should be able to hold a 5” chuck. Admittedly the use of bike parts was partly inspired by CrisB257 on youtube, but I did not want to copy the design completely.

Solution

With the specifications done, the remaining task was to find somewhere to place a brakedisk. This actually took quite some time to figure out, but now it seems simple enough.

On the back of the spindle after the drive pulley is a gear, (part of the leadscrew gearing) after this, a few spacer bushings. I figured that it would be possible to remake the largest spacer, to include brakedisk.

The new brakedisk spacer should look something like this

And this is how it assembles on the spindle.

Next picture show an overview of the complete design: Green designates parts that need fabrication.

Topic will continue in next post.

Last edited: