- Joined

- Dec 21, 2023

- Messages

- 26

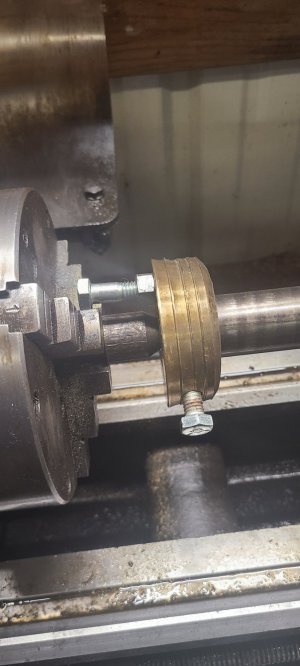

I do not have a proper lathe dog.

I looked in the scrap and found this piece of brass.

It already had a hole just a tad over the proposed work diameter of 1.25" 416SS.

I simply drilled and tapped the side for a 3/8 set screw and the face for a 3/8" drive lug.

Will it likely hold with the diameter being so slose and only one set screw?

Don't worry about hurting my feelings, it is a very short trip back to the scrap bin.

I looked in the scrap and found this piece of brass.

It already had a hole just a tad over the proposed work diameter of 1.25" 416SS.

I simply drilled and tapped the side for a 3/8 set screw and the face for a 3/8" drive lug.

Will it likely hold with the diameter being so slose and only one set screw?

Don't worry about hurting my feelings, it is a very short trip back to the scrap bin.