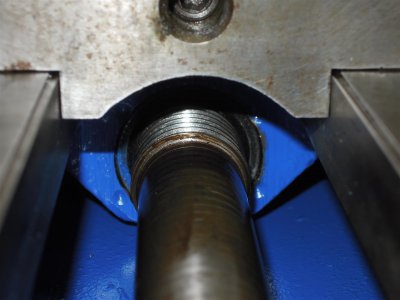

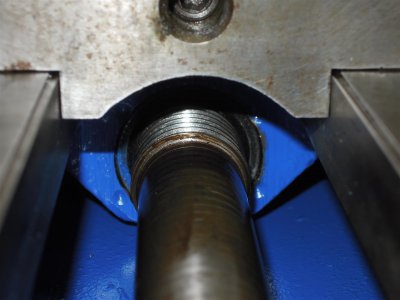

I bought a used 6" Kurt milling vise. I'm not entirely sure what the previous owner did to it, so I don't know if the screw is the right screw for this vise or one that he made for it. When you close your vise fully without anything in the jaws, do the threads protrude from the nut by about an inch or are they entirely contained in the nut? Photo of mine below.

I've repainted the vise. It looks much nicer than when I bought it. The reason I ask is that the seller had a photo of a nice Kurt vise covered in chips in his machining center and hauled out this one when I came to look at it. He told me that when he bought it that the screw was rust frozen in the nut and he worked hard to get it out. When I was at the shop, I didn't fully open the vise, just checked that when it clamped down it was locking. At home I discovered that the jaws wouldn't open fully due to rusty threads in the nut. I solved that with about 2 hours of electrolytic derusting followed by copious brushing and rinsing to get any loose iron oxide (surrogate grinding compound) out of the nut. I noticed that the screw had nearly sharp threads rather than having the flat on top that I associate with a worm thread. Those things made me wonder whether the previous owner made a new screw for the vise after he got out the frozen screw.

I've repainted the vise. It looks much nicer than when I bought it. The reason I ask is that the seller had a photo of a nice Kurt vise covered in chips in his machining center and hauled out this one when I came to look at it. He told me that when he bought it that the screw was rust frozen in the nut and he worked hard to get it out. When I was at the shop, I didn't fully open the vise, just checked that when it clamped down it was locking. At home I discovered that the jaws wouldn't open fully due to rusty threads in the nut. I solved that with about 2 hours of electrolytic derusting followed by copious brushing and rinsing to get any loose iron oxide (surrogate grinding compound) out of the nut. I noticed that the screw had nearly sharp threads rather than having the flat on top that I associate with a worm thread. Those things made me wonder whether the previous owner made a new screw for the vise after he got out the frozen screw.