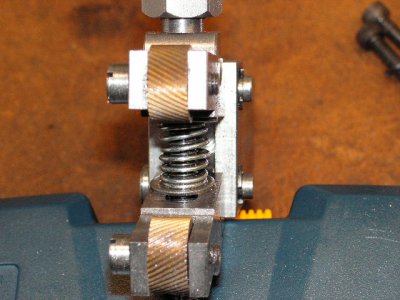

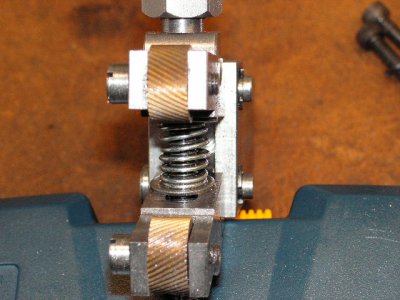

This is a homemade knurling tool. The knurling wheels are made by Dorian,they are OD .750" x

ID .250 x .375 Wide they are coated and the TPI = 20.

My first attemot to use this tool was on a piece of 12L14 approx .700" OD result was not bad,ctr photo. A second attempt was made on a piece of 1018 .875" OD result was a multiple of lines that crisscrossed into each other resulting in one big mess.

The knurling wheels are designated Left Hand (LH) and the other Right Hand (RH) WHAT DOES THIS MEAN? Is there a special way these two wheels are to be arranged? See Photo on the top. Is there a negative significance betweeb using 12L14 as opposed to 1018.

Is the problem is in the differance in diameters. Doing the math (as described in a video) and with a TPI of 20 and using a multiplier 55 is OD = .8745. Using a multiplier of 54 I should reduce the OD to .8586. I'm going to try this in the meantime if anybody out there has suggestion,comments please respond. Thank You