- Joined

- May 20, 2013

- Messages

- 390

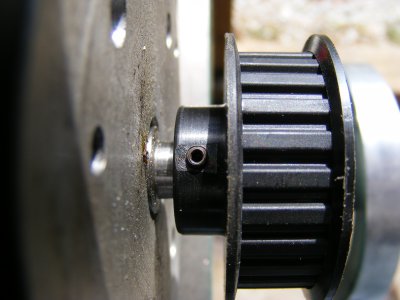

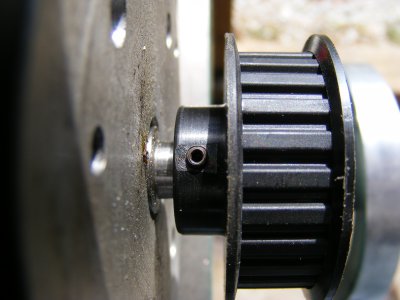

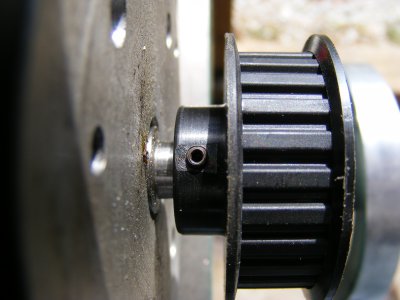

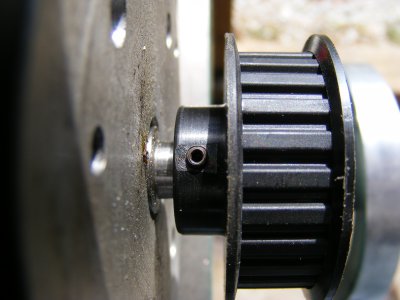

I am working on a belt drive conversion for my Grizzly G0704 mill. The motor drive gear was a press fit on the shaft with a 4mm keyway and key to hold in place, and a snap ring to keep it from coming off the shaft if it ever got loose. I am using stock drive parts to build a cog belt drive. The spindle pulley is done and seems to be securely mounted to the spindle. On the motor pulley I had first tried a single set screw with no keyway. It came loose very quickly. So now I will be cutting a keyway in addition to the set screw. My question is, where, in relation to the set screw, is the best location? Should I put directly 180 degrees from the set screw or is there a better location? The shaft is a 10mm diameter shaft (steel) and the pulley I am using is this one.

I intend to grind a cutter to the right size and make an adapter to hold it in the spindle. Then use the vertical travel of the quill of the mill (not turning) to shave out the keyway in the aluminum hub. I'll clamp the pulley flat to the table and use the table position to control the depth of cut. Any suggestions? Thanks -

Dan

I intend to grind a cutter to the right size and make an adapter to hold it in the spindle. Then use the vertical travel of the quill of the mill (not turning) to shave out the keyway in the aluminum hub. I'll clamp the pulley flat to the table and use the table position to control the depth of cut. Any suggestions? Thanks -

Dan