- Joined

- Jul 8, 2015

- Messages

- 145

I've got a beautiful 16" Walker/Turner (Div of Kearney and Trecker- thus this forum)

But I have a problem- the transmission is stuck! Not in Hi/Low- it works well there...

Its a long post with a lot of pics- so please hang with me and understand Im still learning this stuff!

Here is the face plate- Serial Number 0842 and Model 3331

Here is the Pic of the speed selector and its "Topped out" position-

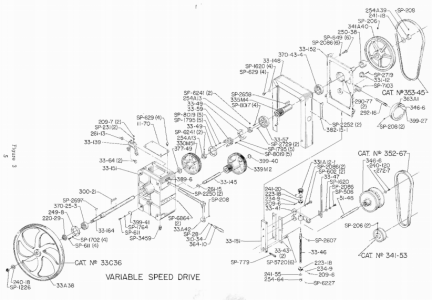

Here is my FIRST issue- I have no idea how to switch/adjust the gear speed- In a recent search I read you should ONLY change speeds while the motor is running- but to me that seems counter intuitive- cannot find anything about this- any experienced K/T guys out there to weigh in on this?

When I got the saw the speed selector was free turning- the problem showed up with the bevel gear and the shafting! The key was turned completely out of the bevel gear- it is on a screw-shaft- here is a pic:

Now I can get this key to seat and screw into the bevel gear by aligning the keyway and key, and slowly turning it counter-clockwise (here is a pic of the shaft seated)

SO I am thinking the "Arm" this screw pushes on is the speed selector as well- (In pic above it is the piece at 90deg under the bevel gear with the RED speed indicator/Flathead screw on.

There are TWO knurled collar rings below the bevel gear. On the screw shaft. One above the speed selector/Speed reducing arm and one above (Here is where it goes horribly wrong as I know nothing about this system- this is a guess!). I would THINK this would lower/raise the arm- Anyone know?

It would appear these rings are loose- they free turn on the shaft- grub screws are loose.

So here is my question- Im thinking I just tighten the bevel gear grub screw to hold the key in place... rotate the knurled TOP knob onto the speed arm and tighten the grub and fire it up! Then adjust DOWN the speed and then raise and secure the lower knurled knob/grub screw.

If you are still reading thank you- get a chuckle and help a dude get some old iron functional!

Please ask questions if I am not clear- Im learning and may not have the right names or thingamabobs identified (Heck- I am doubting its a real bandsaw with all these fiddly bits about!)

Thanks folks!

-Silver

But I have a problem- the transmission is stuck! Not in Hi/Low- it works well there...

Its a long post with a lot of pics- so please hang with me and understand Im still learning this stuff!

Here is the face plate- Serial Number 0842 and Model 3331

Here is the Pic of the speed selector and its "Topped out" position-

Here is my FIRST issue- I have no idea how to switch/adjust the gear speed- In a recent search I read you should ONLY change speeds while the motor is running- but to me that seems counter intuitive- cannot find anything about this- any experienced K/T guys out there to weigh in on this?

When I got the saw the speed selector was free turning- the problem showed up with the bevel gear and the shafting! The key was turned completely out of the bevel gear- it is on a screw-shaft- here is a pic:

Now I can get this key to seat and screw into the bevel gear by aligning the keyway and key, and slowly turning it counter-clockwise (here is a pic of the shaft seated)

SO I am thinking the "Arm" this screw pushes on is the speed selector as well- (In pic above it is the piece at 90deg under the bevel gear with the RED speed indicator/Flathead screw on.

There are TWO knurled collar rings below the bevel gear. On the screw shaft. One above the speed selector/Speed reducing arm and one above (Here is where it goes horribly wrong as I know nothing about this system- this is a guess!). I would THINK this would lower/raise the arm- Anyone know?

It would appear these rings are loose- they free turn on the shaft- grub screws are loose.

So here is my question- Im thinking I just tighten the bevel gear grub screw to hold the key in place... rotate the knurled TOP knob onto the speed arm and tighten the grub and fire it up! Then adjust DOWN the speed and then raise and secure the lower knurled knob/grub screw.

If you are still reading thank you- get a chuckle and help a dude get some old iron functional!

Please ask questions if I am not clear- Im learning and may not have the right names or thingamabobs identified (Heck- I am doubting its a real bandsaw with all these fiddly bits about!)

Thanks folks!

-Silver