- Joined

- Aug 6, 2015

- Messages

- 4,183

New to the forum. Thought I would share a funny story...

Working on my motorcycle fitting wheels that are not for my bike, so a few modifications are required...

Need to remove 1/4" from the caliper mount points to realign with the brake rotor...

I have one of these: 1/3 hp craftman bench drill press

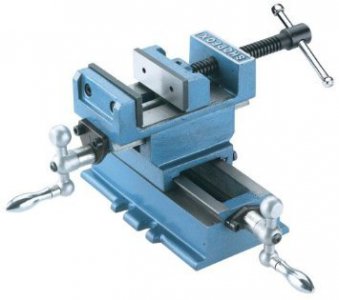

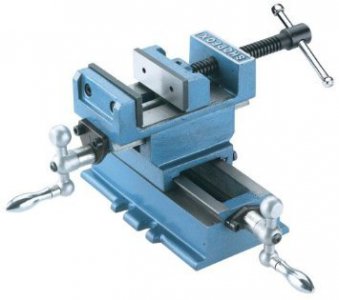

I thought that I could order one of these: Shop Fox D2730 3-Inch Cross Sliding Vise

some milling bits

And be done with it... just to double check, I posted this on the Garage Journal forum...boy was I in for a surprise... quickly learned that a drill press was no replacement for anything that needed lateral forces... so the plan that I had was not the correct approach. Several folks there, that I am grateful for, recommended many different approaches.

Now, I tend to look for any excuse to get tools... someone suggested that I used a milling machine... go to a machine shop and let them do it, use a file and just take my time, etc... but it was the perfect excuse to finally get a milling machine... could not resist doing so...

While I was reading and looking at machines, I went ahead and order a few accessories (ordered the 13/16" 4 Flutes Square End Mill, a vise, some different 4 flute square end mills, fly cutter set, clamping kit, collet set, 1-2-3 blocks, etc)...

I was looking at the Mini... because of the use I will give it, made no sense to get anything bigger... or so I thought...

But then I read about the gear breaking and folks recommending going with the kit to modify it for belt use... so add the cost of that kit (true, not needed from the get go, but it will be required down the line) but when I added the cost of the belt conversion kit, it is close to the next one in size...

But that second one does not include a table...and I needed one... Can you guys see where I am going with this???

This deal from Grizzly (a G0705) is the same machine HF has but with the base/stand... for a couple hundred more....

http://www.grizzly.com/products/Drill-Mill-with-Stand-29-inch-x-8-inch-Table/G0705

Additional 25.00 off shipping cost for signing up for their email news...

Then someone posted... "oh Wachuko, but that is a round collar mill...you should really look for one with a square column" and I am going inside my head, "yeah? so??". I then start reading about round collar mill vs square column mills... then someone mentions the G0704... by now my head is spinning... and I am asking the forum members for help...is the G0704 a better alternative to the G0705 ??? .

http://www.grizzly.com/products/Drill-Mill-with-Stand/G0704

This is the time when another forum member in the Garage Journal site, tells me to take a deep breath and come here to read some more and learn before buying... yeah.. that helped!... I felt like it was going to be 2017 before I could make a decision... you see... then I start reading about CNC conversion kits... I learn that the PM-25MV is similar but with a few more upgrades... arghhhhh!!!

As someone mentioned, I could have used a nail file and I would have been riding my bike by now... anyway... I kept reading, watched videos, looked at the lead times for the delivery of one versus the other... and just made the choice of going with the Grizzly G0704 - Drill/Mill with Stand. I really liked the upgrades that the PM-25MV includes, but I just could not wait that long for it to arrive... So the order was placed today and now I wait for it to arrive!!

I sure hope that I have made the right decision... this is for my garage at home... to make stuff for the bike and small stuff for projects that I have with my cars... and really, just to learn how to make something from a block of metal. My dad was good with all this, and I never learned. With him now gone, I feel like I need to start doing some of this and teach my son as well...

You guys have a great site here!! Looking forward to learning a lot!!

BTW, this is the bike...mounting wheels from a Fat Bob Dyna on a Sportster 48...

One of this days, I will share the time when I went out for milk and eggs and came back with a car...

Working on my motorcycle fitting wheels that are not for my bike, so a few modifications are required...

Need to remove 1/4" from the caliper mount points to realign with the brake rotor...

I have one of these: 1/3 hp craftman bench drill press

I thought that I could order one of these: Shop Fox D2730 3-Inch Cross Sliding Vise

some milling bits

And be done with it... just to double check, I posted this on the Garage Journal forum...boy was I in for a surprise... quickly learned that a drill press was no replacement for anything that needed lateral forces... so the plan that I had was not the correct approach. Several folks there, that I am grateful for, recommended many different approaches.

Now, I tend to look for any excuse to get tools... someone suggested that I used a milling machine... go to a machine shop and let them do it, use a file and just take my time, etc... but it was the perfect excuse to finally get a milling machine... could not resist doing so...

While I was reading and looking at machines, I went ahead and order a few accessories (ordered the 13/16" 4 Flutes Square End Mill, a vise, some different 4 flute square end mills, fly cutter set, clamping kit, collet set, 1-2-3 blocks, etc)...

I was looking at the Mini... because of the use I will give it, made no sense to get anything bigger... or so I thought...

But then I read about the gear breaking and folks recommending going with the kit to modify it for belt use... so add the cost of that kit (true, not needed from the get go, but it will be required down the line) but when I added the cost of the belt conversion kit, it is close to the next one in size...

But that second one does not include a table...and I needed one... Can you guys see where I am going with this???

This deal from Grizzly (a G0705) is the same machine HF has but with the base/stand... for a couple hundred more....

http://www.grizzly.com/products/Drill-Mill-with-Stand-29-inch-x-8-inch-Table/G0705

Additional 25.00 off shipping cost for signing up for their email news...

Then someone posted... "oh Wachuko, but that is a round collar mill...you should really look for one with a square column" and I am going inside my head, "yeah? so??". I then start reading about round collar mill vs square column mills... then someone mentions the G0704... by now my head is spinning... and I am asking the forum members for help...is the G0704 a better alternative to the G0705 ??? .

http://www.grizzly.com/products/Drill-Mill-with-Stand/G0704

This is the time when another forum member in the Garage Journal site, tells me to take a deep breath and come here to read some more and learn before buying... yeah.. that helped!... I felt like it was going to be 2017 before I could make a decision... you see... then I start reading about CNC conversion kits... I learn that the PM-25MV is similar but with a few more upgrades... arghhhhh!!!

As someone mentioned, I could have used a nail file and I would have been riding my bike by now... anyway... I kept reading, watched videos, looked at the lead times for the delivery of one versus the other... and just made the choice of going with the Grizzly G0704 - Drill/Mill with Stand. I really liked the upgrades that the PM-25MV includes, but I just could not wait that long for it to arrive... So the order was placed today and now I wait for it to arrive!!

I sure hope that I have made the right decision... this is for my garage at home... to make stuff for the bike and small stuff for projects that I have with my cars... and really, just to learn how to make something from a block of metal. My dad was good with all this, and I never learned. With him now gone, I feel like I need to start doing some of this and teach my son as well...

You guys have a great site here!! Looking forward to learning a lot!!

BTW, this is the bike...mounting wheels from a Fat Bob Dyna on a Sportster 48...

One of this days, I will share the time when I went out for milk and eggs and came back with a car...

(11.17 mm), doh!

(11.17 mm), doh! User manual, parts diagram, spec sheet... all downloaded!!

User manual, parts diagram, spec sheet... all downloaded!!