- Joined

- Dec 14, 2017

- Messages

- 32

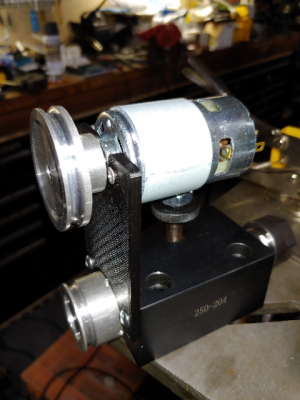

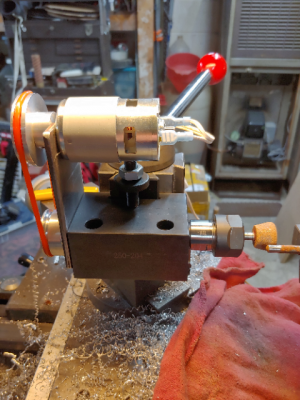

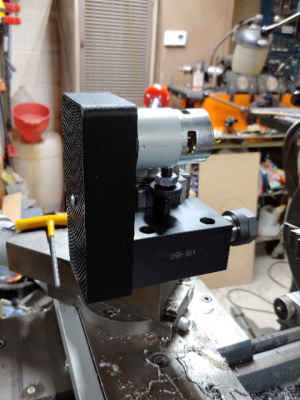

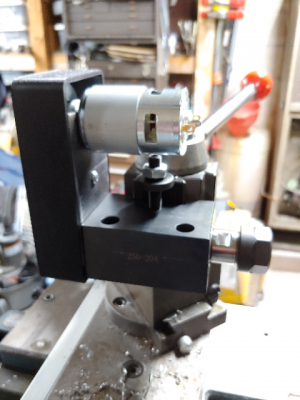

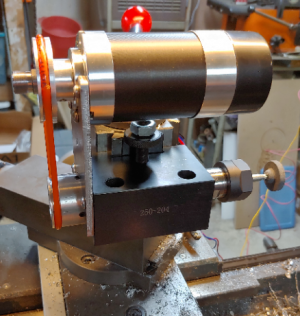

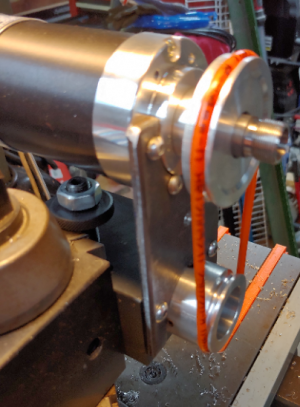

Been looking at all sorts of small tool post grinder ideas for my 1440 lathe and came up with my own take on what might work for my applications.

To be honest I'm not even sure what I will be using it for but decided to build something anyways.

Started with a BXA 1" boring bar holder, ER20 100L arbor, 20x32x7 bearings (started with ABEC 1 but upgraded to ABEC 3 once the concept worked) and a 775 DC motor. Bored the holder for the bearings, machined my own round belt pulley set to fit 4mm belt. Working on a design now for dressing tool holder.

Not sure how the 775 motor will work out, I was impressed with how well it has done in my testing so far. I'm looking at an upgrade for that in the future though.

This is a work in progress and I appreciate all those who have posted their own designs for others to look at, I'm sure you will find your ideas alive in other's projects!

To be honest I'm not even sure what I will be using it for but decided to build something anyways.

Started with a BXA 1" boring bar holder, ER20 100L arbor, 20x32x7 bearings (started with ABEC 1 but upgraded to ABEC 3 once the concept worked) and a 775 DC motor. Bored the holder for the bearings, machined my own round belt pulley set to fit 4mm belt. Working on a design now for dressing tool holder.

Not sure how the 775 motor will work out, I was impressed with how well it has done in my testing so far. I'm looking at an upgrade for that in the future though.

This is a work in progress and I appreciate all those who have posted their own designs for others to look at, I'm sure you will find your ideas alive in other's projects!