- Joined

- Dec 17, 2012

- Messages

- 745

I'll have to drill the head of some 40" (1 metre) aluminum bars with the ubiquitous Cheapex brand 350W 5-speed bench drill press, a close relative of the Baby Grizzly, having just a 13" space below the chuck.

To cut a large hole in the base of the drill and to place it over a tall table with a corresponding hole doesn't seem to me a great idea, so I'm thinking to another solution.

My drill is on a high standalone cart, with the back rounded to have the chuck always hanging out of the table if I turn the head around the column (I made that years ago: sometimes I'm prescient).

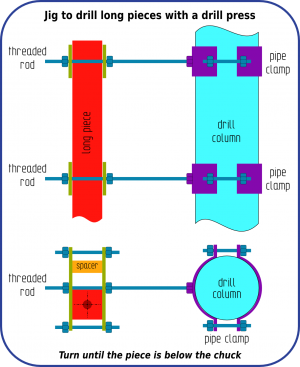

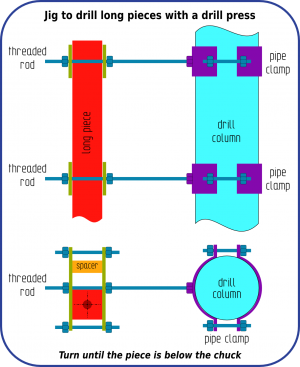

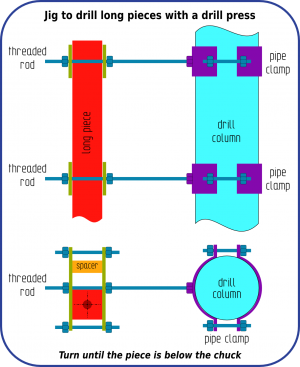

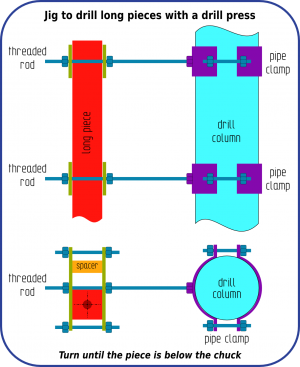

I'm planning to place on the drill column a couple of pipe clamps, those with an M8 screw to be inserted into a wall plug - the Italian version here: http://www.fischeritalia.it/static/prodotti/fissaggi_idrotermosanitari/CGITS_CPT.pdf - screwing a threaded rod into them.

The aluminum bar will be held outside the table between two plates, acting like the jaws of a vise, moving along the threaded rods and locked with nuts. Maybe the image gives a better idea of this jig.

To keep the head of the bar in the right position, then, all I have to do is to move the jaws along the threaded rods until the bar is true with the drill bit.

Since these clamps don't give a great vertical support, I'll place some bricks and a machinist jack on the floor, and a bag of cement on the drill base to act as a counterweight. I'll take some photos when I'll make this job.

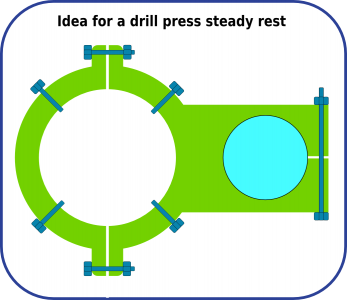

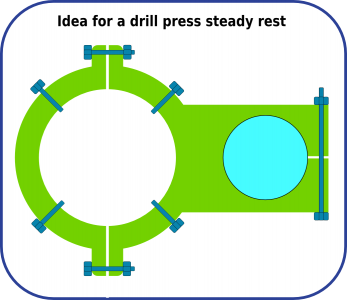

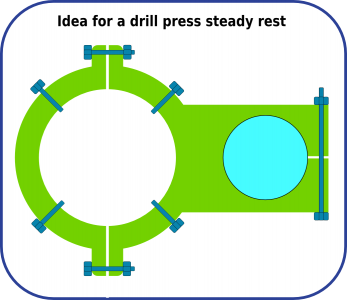

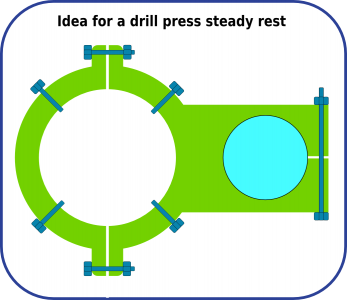

I think this jig (or is it a fixture?) could be useful even for who has a high drill, because long parts can't be precisely held, if the vise is too far: think to something like a lathe steady rest running up and down along the column. Here is my idea of it.

If the piece you have to drill is really tall, you can hang your drill out of a 2nd or 3rd floor window (but in this case don't forget a heavy counterweight!!!).

Do you think there is a better way to do this?

Marco

To cut a large hole in the base of the drill and to place it over a tall table with a corresponding hole doesn't seem to me a great idea, so I'm thinking to another solution.

My drill is on a high standalone cart, with the back rounded to have the chuck always hanging out of the table if I turn the head around the column (I made that years ago: sometimes I'm prescient).

I'm planning to place on the drill column a couple of pipe clamps, those with an M8 screw to be inserted into a wall plug - the Italian version here: http://www.fischeritalia.it/static/prodotti/fissaggi_idrotermosanitari/CGITS_CPT.pdf - screwing a threaded rod into them.

The aluminum bar will be held outside the table between two plates, acting like the jaws of a vise, moving along the threaded rods and locked with nuts. Maybe the image gives a better idea of this jig.

To keep the head of the bar in the right position, then, all I have to do is to move the jaws along the threaded rods until the bar is true with the drill bit.

Since these clamps don't give a great vertical support, I'll place some bricks and a machinist jack on the floor, and a bag of cement on the drill base to act as a counterweight. I'll take some photos when I'll make this job.

I think this jig (or is it a fixture?) could be useful even for who has a high drill, because long parts can't be precisely held, if the vise is too far: think to something like a lathe steady rest running up and down along the column. Here is my idea of it.

If the piece you have to drill is really tall, you can hang your drill out of a 2nd or 3rd floor window (but in this case don't forget a heavy counterweight!!!).

Do you think there is a better way to do this?

Marco