- Joined

- May 5, 2013

- Messages

- 11

Hello all!

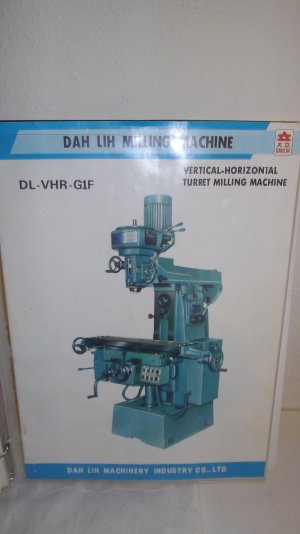

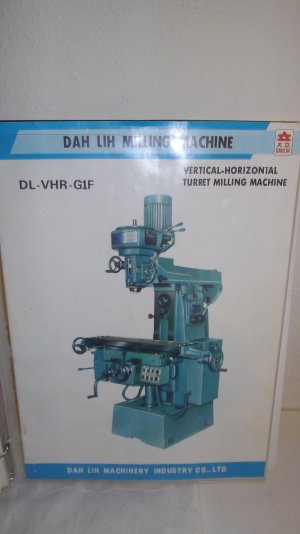

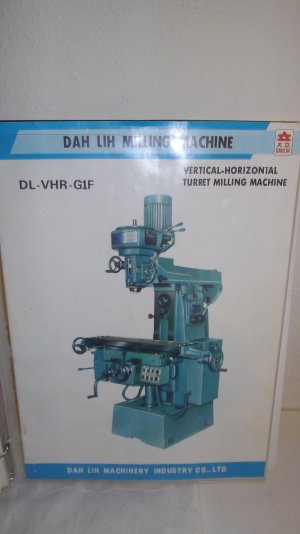

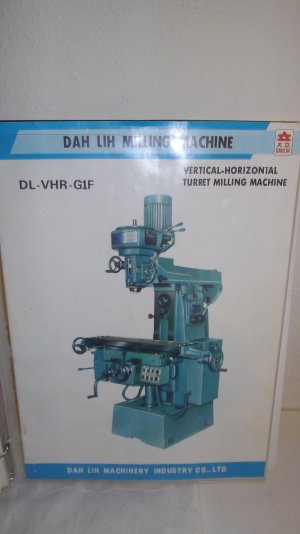

New user & first post. I got involved in machining while earning my degree, but nothing really in depth. Recently, a gunsmith friend asked if he could put his old Craftsman 101 series lathe in my shop for his personal use. That was the beginning of the end. I had to have a mill. I got together with an old friend who is a retired a mold & tool maker for NASA & Boeing (experience counts), and we found this 1980 JET (Dah Lih) horizontal/vertical mill for about $4.5K.

Only a couple thou backlash on all axis. We couldn't believe how new this thing seems. It is missing the horizontal arbor, but they're cheap online, and my old machinist buddy kinda wants to make me one.

It also came with a heap of tooling, and the actual original manual and QA inspection forms.

I purchased an ETM NMTB 30 ER40 Chuck and collet set online, and have been given a mountain of blocks, end mills, gauges, taps, etc... from my buddy, bless his heart. The phase converter is on the way, so once I bet it into final position, and have 'er hooked up, I'll be making my first chips at home!

On a side note, how do you folks move things like 12" rotary tables around? The thing must weigh more than I do. Every time I haul it around my back aches for days.

New user & first post. I got involved in machining while earning my degree, but nothing really in depth. Recently, a gunsmith friend asked if he could put his old Craftsman 101 series lathe in my shop for his personal use. That was the beginning of the end. I had to have a mill. I got together with an old friend who is a retired a mold & tool maker for NASA & Boeing (experience counts), and we found this 1980 JET (Dah Lih) horizontal/vertical mill for about $4.5K.

Only a couple thou backlash on all axis. We couldn't believe how new this thing seems. It is missing the horizontal arbor, but they're cheap online, and my old machinist buddy kinda wants to make me one.

It also came with a heap of tooling, and the actual original manual and QA inspection forms.

I purchased an ETM NMTB 30 ER40 Chuck and collet set online, and have been given a mountain of blocks, end mills, gauges, taps, etc... from my buddy, bless his heart. The phase converter is on the way, so once I bet it into final position, and have 'er hooked up, I'll be making my first chips at home!

On a side note, how do you folks move things like 12" rotary tables around? The thing must weigh more than I do. Every time I haul it around my back aches for days.