- Joined

- Apr 21, 2013

- Messages

- 208

I disassembled my Jacobs 14N chuck yesterday and thought I'd share some photos. I imagine this chuck is similar to most of Jacobs ball bearing chucks.

Mine worked great from 1/4" to 1/2", but was binding below 1/4" and wouldn't even tighten up past 1/8".

I started by pressing the outer ring off of the chuck. You'll need a ring to fit this position of the chuck (photo 1)

Once the outer ring is removed, you can remove the bearing balls through the small notch, at which point the split race will come off.

Here are all the parts of the chuck. Since each jaw is different, when I removed each jaw, I made a note as to which one was in which position of the chuck (actually, I took a photo that showed the teeth of the jaw and the lettering on the chuck so I'd know what position to put them back in later)

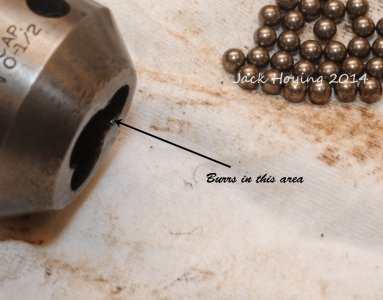

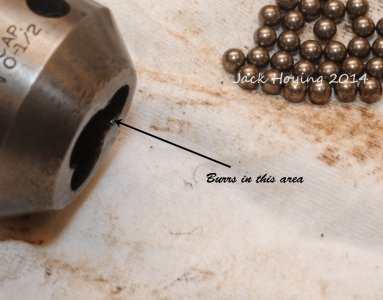

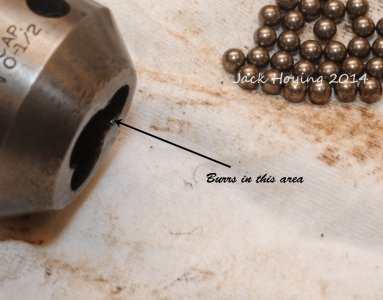

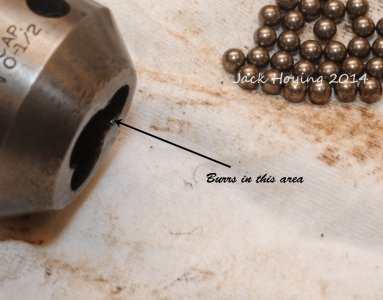

After a through cleaning, the jaws still wouldn't operate smoothly in the farthest out position. It turns out that there were a few small burrs at the mouth of the chuck. I used a fine stone in a Dremel tool to clean them up and that took care of the problem completely.

To reassemble, reverse the process and press the outer ring back on, using the key teeth as the position to press against.

Jack

Fort Loramie, Ohio

Mine worked great from 1/4" to 1/2", but was binding below 1/4" and wouldn't even tighten up past 1/8".

I started by pressing the outer ring off of the chuck. You'll need a ring to fit this position of the chuck (photo 1)

Once the outer ring is removed, you can remove the bearing balls through the small notch, at which point the split race will come off.

Here are all the parts of the chuck. Since each jaw is different, when I removed each jaw, I made a note as to which one was in which position of the chuck (actually, I took a photo that showed the teeth of the jaw and the lettering on the chuck so I'd know what position to put them back in later)

After a through cleaning, the jaws still wouldn't operate smoothly in the farthest out position. It turns out that there were a few small burrs at the mouth of the chuck. I used a fine stone in a Dremel tool to clean them up and that took care of the problem completely.

To reassemble, reverse the process and press the outer ring back on, using the key teeth as the position to press against.

Jack

Fort Loramie, Ohio