- Joined

- Nov 5, 2020

- Messages

- 31

Hi Guys,

Well, I went and bought a bigger lathe than my little harbor Freight.

I found a J.J. McCabe model 4010 just an hour away.

Some information:

Bed length 78 inches

38 inches between centers

Center of chuck to bed 7 1/4 inch

3 jaw 9 inch chuck.

1 1/4 bore ( I think)

Change gears

Lantern tool post

Power cross feed

10 inch back plate

Dead centers (3)

Jacobs chuck

Lots of HSS

The guy had it on market place for two weeks. Only had a few look at it.

I drove there Sunday and fell in love with it. The current owner does not need the lathe and just wanted to get it out of the shop. He is 76 years young and can remember it sitting in the exact spot when he was just a boy. The lathe and shop belonged to his father.

First thing I did was clean the grease and dust from the ways and they looked great. There was some damage near the chuck end (small dents), but other than that I could not see much wear. From what I was told it has been sitting there for over 60 years and was from the early 1900's. Have yet to find a serial number. The whole machine was covered in this layer of black grease, which probably preserved it as there was no rust.

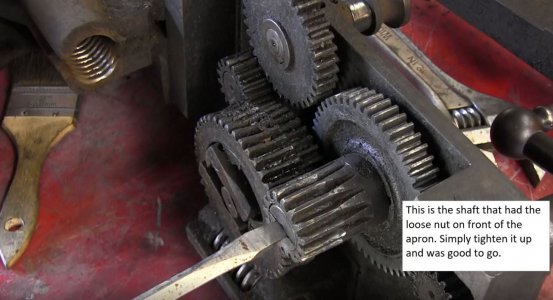

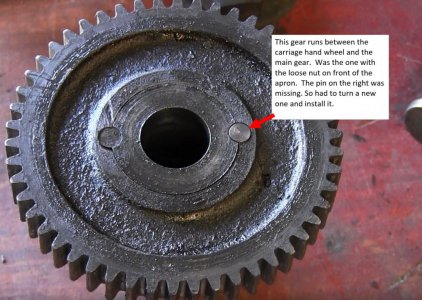

Behind the lathe was a cone spindle mounted to the wall which was turned by an electric motor in the rafters. It fired up and ran with no problems but the flat belt was in bad shape. Other than that there is a loose gear in the apron that has to be addressed.

I cannot really believe the lathe sat there so long without any takers. He was asking 450 dollars for the machine.

In the mean time since I got it home I have been online looking for information on the unit but have hit a dead end. There is not much out there on the J.J. McCabe lathes. Would love to find a manual but does not look good.

Tomorrow I am going to start the inspection and cleaning process. Goin to pull the apron and check out the loose gear. BTW this thing is heavy!

I am going to take plenty of pictures and video the restoration. See if I can document as much as possible.

Attached is the picture from the original listing.

Well, I went and bought a bigger lathe than my little harbor Freight.

I found a J.J. McCabe model 4010 just an hour away.

Some information:

Bed length 78 inches

38 inches between centers

Center of chuck to bed 7 1/4 inch

3 jaw 9 inch chuck.

1 1/4 bore ( I think)

Change gears

Lantern tool post

Power cross feed

10 inch back plate

Dead centers (3)

Jacobs chuck

Lots of HSS

The guy had it on market place for two weeks. Only had a few look at it.

I drove there Sunday and fell in love with it. The current owner does not need the lathe and just wanted to get it out of the shop. He is 76 years young and can remember it sitting in the exact spot when he was just a boy. The lathe and shop belonged to his father.

First thing I did was clean the grease and dust from the ways and they looked great. There was some damage near the chuck end (small dents), but other than that I could not see much wear. From what I was told it has been sitting there for over 60 years and was from the early 1900's. Have yet to find a serial number. The whole machine was covered in this layer of black grease, which probably preserved it as there was no rust.

Behind the lathe was a cone spindle mounted to the wall which was turned by an electric motor in the rafters. It fired up and ran with no problems but the flat belt was in bad shape. Other than that there is a loose gear in the apron that has to be addressed.

I cannot really believe the lathe sat there so long without any takers. He was asking 450 dollars for the machine.

In the mean time since I got it home I have been online looking for information on the unit but have hit a dead end. There is not much out there on the J.J. McCabe lathes. Would love to find a manual but does not look good.

Tomorrow I am going to start the inspection and cleaning process. Goin to pull the apron and check out the loose gear. BTW this thing is heavy!

I am going to take plenty of pictures and video the restoration. See if I can document as much as possible.

Attached is the picture from the original listing.