- Joined

- Apr 23, 2011

- Messages

- 2,476

Tarmo, I think you have missed something in GK's postBut my question is how did you cut the gear.

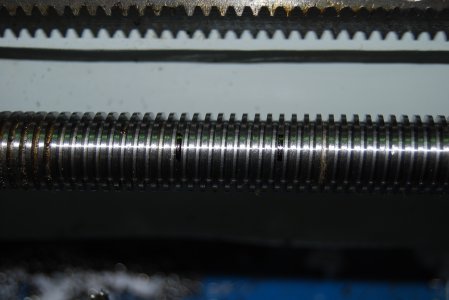

He copied the leadscrew pattern onto the gear blank and then using a small grinder, Think Dremel tool, to cut the teeth freehand......I brushed on the blackest grease/oil on the lead screw and rolled the delrin to get the imprint..........die grinder with cut off I cut the teeth on the bench vice. As you get a pretty good mesh thats good enough. ......

Cheers Phil