- Joined

- Sep 12, 2020

- Messages

- 56

Hey guys,

I made this video as an introduction and to "show off" my new Atlas Lathe. I got this guys from my father who had it in a back shed and am extremely excited to start playing with it.

I'm a knife maker and youtuber... and I plan on using this guy to make fasteners, finniels, pomel nuts, etc. Will probably be making a good deal of tools with it as well.

I've been gathering up a few questions and this forum seems like the best place on the internet to get answers on these lathes. I'm new to lathes... so I apologize if some of these are very basic... newbish.

I'm super happy I found this Forum,

James

Red Beard Ops

I made this video as an introduction and to "show off" my new Atlas Lathe. I got this guys from my father who had it in a back shed and am extremely excited to start playing with it.

I'm a knife maker and youtuber... and I plan on using this guy to make fasteners, finniels, pomel nuts, etc. Will probably be making a good deal of tools with it as well.

I've been gathering up a few questions and this forum seems like the best place on the internet to get answers on these lathes. I'm new to lathes... so I apologize if some of these are very basic... newbish.

- How do I classify/name this lathe?

- Based on the 10D-247 and some other searches I've been doing I think I would call this a 10''x24'' lathe. This first number is the swing,right? With a tape measure the distance between the center and table is about 6'', so wouldn't the swing be a 12''?

- Does the 101.07361 give a good indication of date of manufacture?

- Looking though the Atlas DB yall have in the stickies, I only found one that matched and it was dated in the 1030s.

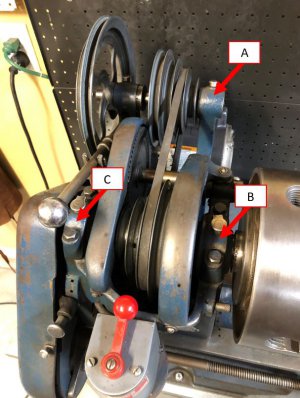

- Is the vibration in the video normal?

- It appears that someone installed a replacement motor on this lathe

- Maybe I need new V-Blets?

- It had an 8'' chuck on it. This seemed large to me, is it the normal size for this machine?

- Are there limitations to using 1/4'' tooling? Just seems small in comparison to what I've been seeing online.

- Any other suggestions on checks, cleaning, tooling, etc

I'm super happy I found this Forum,

James

Red Beard Ops