- Joined

- Oct 4, 2016

- Messages

- 7,023

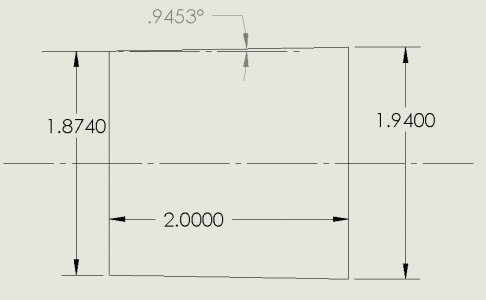

I was asked to do a project to cut a 5" diameter aluminum bar into 2" sections, and bore a hole in the center. I said sure bring it over. Well I have the bar and the fitting that they want it bored out for, what they did not tell me is that it is tapered, and slotted. I would like to get some guidance for this project please.

Major diameter is 1.940,

the minor diameter is 1.874

The taper calculator I looked up says I have a 1.909 taper angle, and a .06667 taper per inch. The fitting is 1.5" to the shoulder, I'm wondering about what kind of fit do I bore this out to. Also is the math correct, I'm debating about using the compound/cross slide vs the taper attachment. I have it bored out to the minor diameter right now.

Major diameter is 1.940,

the minor diameter is 1.874

The taper calculator I looked up says I have a 1.909 taper angle, and a .06667 taper per inch. The fitting is 1.5" to the shoulder, I'm wondering about what kind of fit do I bore this out to. Also is the math correct, I'm debating about using the compound/cross slide vs the taper attachment. I have it bored out to the minor diameter right now.

Last edited: