David Best's book is very good at explaining the indexable tooling jargon and highly recommended, but once you follow the nomenclature it is pretty straight forward. The difficulty is figuring out what works best for one's machine. When it comes to inserts it gets even crazier because there are so many variants of the same style/type of insert, as well as the proprietary types that each manufacturer comes up with. At a hobbyist level, for the most part, you are less interested in maximizing metal removal and insert life, and the operating characteristics are very different than a production environment.

I switched to laydown threading inserts after trying the typical vertical type threaders, both with carbide and HSS inserts and not having very good results, and in some cases ruining the project at the final threading stage. The laydown type inserts as well as the captured/clamped inserts like the Kennametal support the insert better and in my experience hold-up much better. My previous lathe was a PM-1340GT, and it worked just as well with the laydown threading insert as current lathe which is much more stout. I have attached some recommendations on the indexable tool holders that I use, as a reference starting point. There is a range of tooling/inserts that is vast, and different approaches that one can take, the idea is to narrow down the choices and find out works for each machine. So this is just what has worked for me. The information attached is to help understand some of the nomenclature and some suggested tooling.

Laydown threading holders/inserts come in 4 variants, which has to do with external threading or internal threading, and then right hand threading and left hand threading. This has to do with the angle of the insert in the seat and the clearances of the insert. I just have the right hand threading holders, although I have cut left hand external threads with the right hand holder. See below, the left hand was a longer Allen bolt that I threaded the shank section, these were used as retaining axels for wheels.

On the Grizzly 1236 size lathe with BXA holders then I would recommend 5/8" indexable tool holders for threading so:

Insert Holders: I would get one for external threading and one for internal threading (Right Hand)

SER 0625 H16, SER is laydown threader, External threading, Right hand thread, H is the length, 16 is the size of the insert.

SIR 0625 P16, SIR is laydown threader, Internal threading, Right hand thread, P is the length, 16 is the size of the insert.

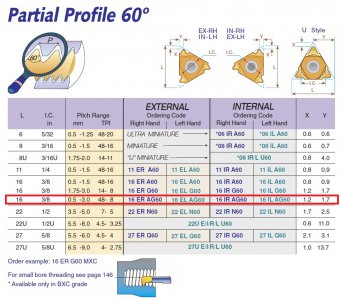

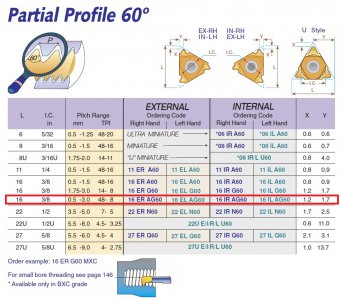

Inserts: These are what are called as partial threaders which cover a range of TPI. I would get two of each.

16 ER AG60 BMA, 16 is the size, External Right Hand thread, AG60 type and threading range, BMA is the coating (which is suitable most metals).

16 IR AG60 BMA, 16 is the size, Internal Right Hand thread, AG60 type and threading range, BMA is the coating (which is suitable most metals).