-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Info needed for installing/setting up pm940m

- Thread starter tim81

- Start date

- Joined

- Dec 18, 2022

- Messages

- 2,610

He is just attempting to tighten it, I think...If you want to remove the gib, you will likely need to take a soft drift (brass or wood) and tap it up.

- Joined

- Dec 18, 2022

- Messages

- 2,610

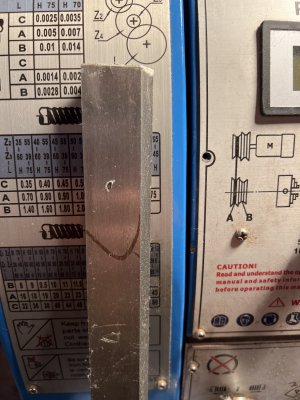

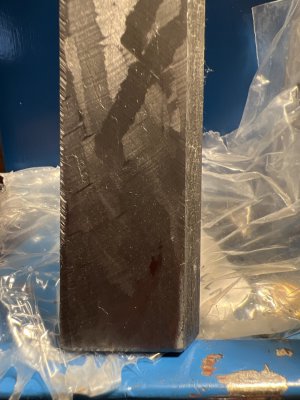

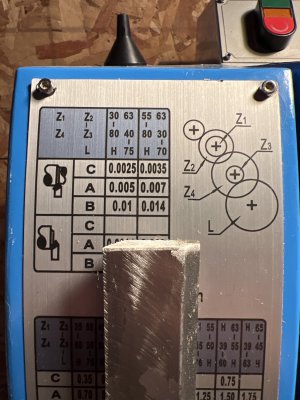

Yeah, if you have a fine flat stone, like you would use to sharpen a knife, needs to be flat, clean that up and carefully flatten the sides of that with the stone, use a little thin oil like "3 in 1", you do not want to cut it just make the surfaces smooth and flat.The lower bolt had a little pice on meta on firts thread

I think they assembled the unit and than put the paint on as it had gotten inside. Maybe that was why it was impossible to screw it. I put not much force on it as I was afraid of damaging it

Attachments

- Joined

- Dec 18, 2022

- Messages

- 2,610

Hey Tim, call PM Tech and share those pictures with him, that thing is rough, if you debur it and stone it smooth it should work but that is rough for a gib. B2/David, are you seeing this? Thoughts?I think they assembled the unit and than put the paint on as it had gotten inside. Maybe that was why it was impossible to screw it. I put not much force on it as I was afraid of damaging it