Thank you for explaining that process. I had no idea it was so much work just to make the drawings available. Your drawings are excellent and had all the data needed to create my own models and stl files. Take a break from the digital lathe and enjoy putting your real one back together.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm making a CAD model of my Atlas 618 and need some help

- Thread starter mvagusta

- Start date

- Joined

- Apr 28, 2024

- Messages

- 5

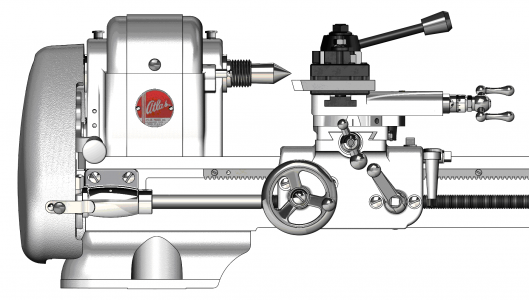

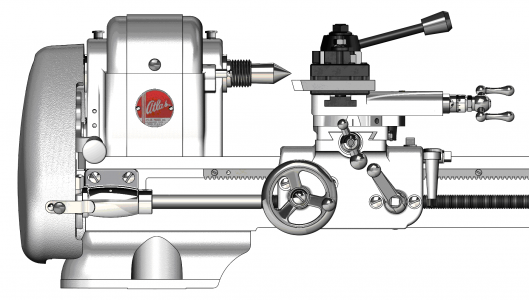

Props to you, incredible work! Without people like you, knowledge of these old machine would be lost forever. I'm glad your apart of the machinist community.I got a seat of the Solidworks CAD system for Christmas (whooah!) and in the middle of January I started modeling the Atlas 618 lathe (serial number 011120) that a friend gave to me a while back. The lathe is now completely disassembled and the parts are being measured using hand tools like machinist scales, dial calipers, micrometers, and a tape measure. I have been working steadily on it and am getting near the end of phase 1, which is creating the basic model. Phase 2 is checking dimensions, fits, and tolerances. Phase 3 is drawings of selected parts. Phase 4 is solid models of selected parts for 3D printing. Below are some images of the lathe and the model so far. I couldn't find any reference on the site for what size is recommended for direct embedded images, so I hope these are OK. The things I could use some help about are at the end.

View attachment 445032

View attachment 445034

View attachment 445035

I could use some guidance in the following areas:

View attachment 445038

- Atlas/Clausing drawings. The only really useful one I have is for the spindle. These will be used to check my guesswork on items that were difficult or impossible to measure with the tools I have available. If anyone has images of any drawing for this lathe that is not already on this website, I would be glad to obtain a copy. Just about any digital format will do.

- Does Atlas/Clausing still provide digital images of drawings for this lathe? If so, a phone number and contact would be helpful.

- As long as I have the machine apart, I think I will paint it and I think I want to use a machine paint that can be brushed on. Recommendations as to paint type or application technique or experiences related to this would be welcome. For example, after cleaning a cast iron casting and prepping for paint, which means removing any lubricants such as grease and oil, how can one prevent rust from forming on the unpainted areas while the paint is curing?

- There are a few parts that I do not have. If you would be willing to send me measurements of any of the following, that would be great.

- 9-88 MT2 dead center from the M6-31X spindle assembly

- L2-80 MT1 dead center from the M6-5X tailstock assembly

- 9-41 toolpost rocker from the M6-39X tool post assembly

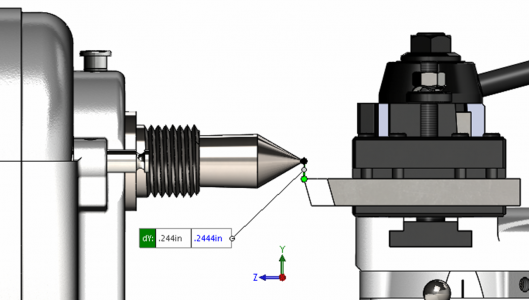

- I have the ability to scale a photo to determine measurements using the CAD system. A photo of one or more of these parts with a reasonably accurate measurement of the part's longest dimension can be used like a crude optical comparator. It works best if the photo is taken from a distance, at least 6 feet and the farther the better, to reduce optical distortion. Example below.

Is this fun, or what?

Thanks for any assistance you can give.

- Joined

- Apr 28, 2024

- Messages

- 5

Any update on the rebuild?Thanks for the complements, you are all very kind.

As far as making STL files for 3D printing ... I plan to do that but not until I finish a few other things like clean, strip, and paint the lathe castings, put the lathe back together, finish the bench I am building to mount it on, build a leveling system, mount and level the lathe, and get it running.

Also, I have not yet figured out how to handle the sharing of various file formats in a way that is not going to be a nightmare of data entry, change tracking, and upkeep for me. None of the vintage machinery forums to which I belong is set up for this kind of file management, including this one. What I'd like to find is a vault where I can just dump the latest files as a group transfer (no data entry) on a site that is public-minded (open source, public domain, free to access, etc.), that can handle binary files easily, and isn't owned by a company that asserts rights on whatever is put there. I have looked at GrabCAD, GitHub, SourceForge, and a few other places I can't recall without finding anything that seems to fit the bill.

The issue is that the number of files to be managed has the potential to be huge. Here are the stats for the CAD model:

Total components in Atlas 618 Lathe - ASSY: 374Parts: 349Unique Part Documents: 233Unique Parts: 232Subassemblies: 25Unique Subassemblies: 24Unique Subassembly Documents: 24Maximum Depth: 4Number Of Top Level Components: 14Resolved Components: 373Resolved Documents: 256Lightweight Components: 0Suppressed Components: 1Hidden Components: 0Virtual Components: 0Envelope Components: 0Number Of Bodies: 394Number Of Total Evaluated Mates: 30Top Level Mates: 34Flexible Subassembly Mates: 0

There are a number of file formats that folks are likely to want, such as STL, Parasolid (.x_t), IGES, STEP, and DXF. SolidWorks can save a file in all of these formats and 20 more. I don't even know what half of them are.

I uploaded 180 PDF drawings to Hobby-Machinist Downloads section and it was a little painful. Took me 20-30 hours. Very dull. Files must be uploaded one at a time. Searchable information is entered in 5 blank fields labeled Title, Tag Line, Type (this is actually the file being uploaded), Version Number, and Description. Because the system does not offer a preview to a person who might want to download the file, a graphic image of the part and a thumbnail of the drawing are created and pasted into the Description box. (Otherwise a person would have to download a file to find out what it really is., which is a pain) This process is repeated for each file that is uploaded to the site.. So it was a lot of work that was less than exciting for just 180 drawings. (Not that I am complaining, I was happy to do that. I just don't feel like doing it again.) If I saved 256 model files in 3 different 3D formats, that would be 768 files to upload and to enter data for each file one at a time. I am laughing to myself at the idea of doing that or even half of that. I can't think of anything that would motivate me to want to do that.

I am open to suggestions. I may end up doing DropBox or Google Drive or something like that. But not before the lathe is up and running. This is what it looks like at the moment ...

View attachment 484973

- Joined

- Jul 2, 2022

- Messages

- 50

Thank you. I learned quite a bit in the process and had some fun.

As far as an update goes, I am waiting for a few weeks before stripping and painting because my garage is unheated and it is still not warm enough for painting. We are expecting snow this week.

Here is the current state of the lathe:

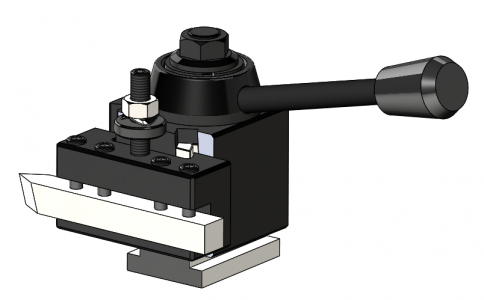

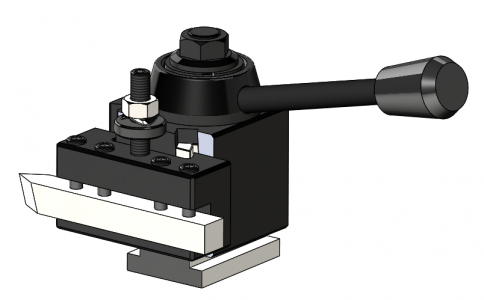

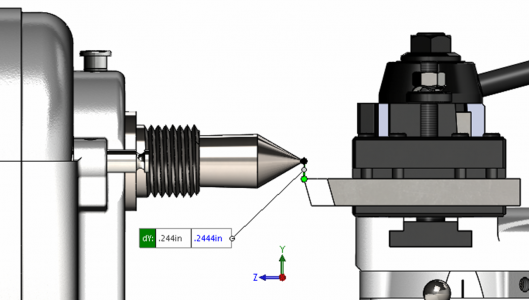

In the meantime I looked for a short-term project that I could do indoors and decided to purchase a quick change tool post (QCTP) and model it. The lantern-style tool holder that came with the lathe is damaged and incomplete, so a QCTP was on the to-do list. Research showed that the AXA size tool post is too big for the Atlas 618 so OXA was the way to go. I heard that the Shars OXA was one of the higher quality Chinese imports, so I bought one, took it apart, measured it, and modeled it. That last part was more difficult than imagined.

Here are some images:

The last image shows that with a 3/8" tool bit and the tool holder lowered to the bottom of full-contact travel there is roughly 1/4" of clearance below center. It can't be seen from these images, but the tool holder cannot be rotated on the compound slide because the casting behind the mounting surface is not flush ... it sticks up around .138" on my lathe. As a workaround a spacer could be put under the QCTP to clear the casting but it would reduce the maximum clearance below center. It would be interesting to know what others have discovered in using a QCTP on this lathe.

As far as an update goes, I am waiting for a few weeks before stripping and painting because my garage is unheated and it is still not warm enough for painting. We are expecting snow this week.

Here is the current state of the lathe:

In the meantime I looked for a short-term project that I could do indoors and decided to purchase a quick change tool post (QCTP) and model it. The lantern-style tool holder that came with the lathe is damaged and incomplete, so a QCTP was on the to-do list. Research showed that the AXA size tool post is too big for the Atlas 618 so OXA was the way to go. I heard that the Shars OXA was one of the higher quality Chinese imports, so I bought one, took it apart, measured it, and modeled it. That last part was more difficult than imagined.

Here are some images:

The last image shows that with a 3/8" tool bit and the tool holder lowered to the bottom of full-contact travel there is roughly 1/4" of clearance below center. It can't be seen from these images, but the tool holder cannot be rotated on the compound slide because the casting behind the mounting surface is not flush ... it sticks up around .138" on my lathe. As a workaround a spacer could be put under the QCTP to clear the casting but it would reduce the maximum clearance below center. It would be interesting to know what others have discovered in using a QCTP on this lathe.

- Joined

- Apr 28, 2024

- Messages

- 5

Nice model of the QCTP. Here's my Atlas/Craftsman 618, I restored in 2016, has an OXA QCTP from littlemachineshop.com (Not Pictured)

Have you decided the upload the Cad Models yet? I asked because, lets just say I took a little too aggressive cut and broke the compound rest swivel....

View attachment 488531

Have you decided the upload the Cad Models yet? I asked because, lets just say I took a little too aggressive cut and broke the compound rest swivel....

View attachment 488531