- Joined

- Sep 22, 2021

- Messages

- 115

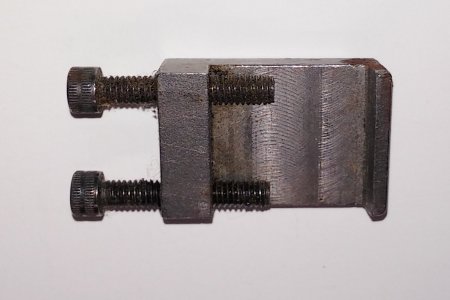

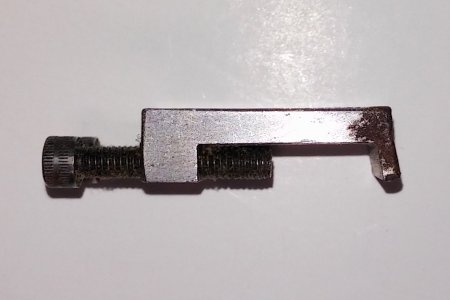

Here's one of the vise stops I mentioned. It's beat up, but it's quick & easy to make. This one is made from a 3/8" x 7/8" cold rolled bar and it has two 8-32 Allen cap screws to hold it in place on the back jaw. I prefer to make these out of mild steel so if an end mill should contact it, the end mill isn't damaged.