-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideas for Scroungers

- Thread starter KenS

- Start date

- Joined

- May 14, 2013

- Messages

- 237

How do you get them out? Is it a messy process?

Quite simple and clean! I just use a small "o" ring pic to puncture a itty bitty hole right next to the rolled edge of the base of the can( after I have bled off pressure to be absolutely certain it is empty ) then grab the center top portion with either side or end cutting pliers and lever the small center piece out. Clean with a little solvent and voila tiny but strong springs.

Last edited:

- Joined

- Aug 7, 2013

- Messages

- 655

John,

I got the idea from another forum. I would post the link here but would risk the rath of Nelson. PM me for details.

Chuck

Chuck

Don't post a link. Post the idea.

DAN_IN_MN,

It was not my idea, and I would not wish to insult the originator by making it look as such. I will provide the link to anyone that wishes via PM or e-mail. The tool is simple enough to figure out from the picture I posted.

I am a member of many forums and this is the only one that prohibits links to ideas or creativity on other forums. I don't feel the need to re-invent the wheel.

Chuck

It was not my idea, and I would not wish to insult the originator by making it look as such. I will provide the link to anyone that wishes via PM or e-mail. The tool is simple enough to figure out from the picture I posted.

I am a member of many forums and this is the only one that prohibits links to ideas or creativity on other forums. I don't feel the need to re-invent the wheel.

Chuck

I just bought my lathe & mill, so i haven't had a chance to build anything with the scrap I've found, so I don't know how well some things will machine. So far I have a couple of old flywheels that I want to make a large steady rest from. I have a long shaft from a hydraulic engine hoist, about 1.5" diameter & 30" long, & looks to be hardened, smooth & straight. I'm going to try to use it for lathe headstock, tailstock alignment.

Old car engines & transmissions have lots of good nuts & bolts, shafts & gears. I have saved a couple of car struts & a pair of leaf springs. I salvaged an old rack mount computer console, it had some nice pieces of 1/4" Almuinum plate, lights, fans, switches, & wire.

Keep your eyes open, & sometimes you get lucky. I found a couple of huge bolts half buried on the side of the road when I stopped to fix a flat, the bolts where about 18 inches long & 2 inches in diameter, I have no idea what they would have went to, a bridge maybe. I've run across stuff put in the woods before, but never tried to salvage any of it. Old cars, ovens, Old farm equipment has literally tons of good material on it. I also found an old school wood stove that was a couple hundred pounds of cast iron.I've found some good hardware being thrown out during/after a building remodel near my house, light fixtures, a bunch of little bags of bolts & screws, a chunk of counter top, a couple of ceiling fans. I got them all for free buy talking to the owner when I was walking the dog. Put the ceiling fans in the garage with 3 100watt CFL bulbs in them, really added some light in there, plus the 3 of the 4 four light fixtures worked fine, put those in the attic so I can see what's stored up there better.

I've gone to auctions, a few times, & it's amazing what you'll find. The longer you stay the better deals you'll get. I've also seen people go nuts at auctions & pay more for used stuff than what the same item would cost new at the store. Same thing at flea markets, at the end of the day you get amazing deals, some people will give you stuff just so they don't have to haul it back home.

By far the best scrounger I've ever seen is my girlfriends retired father. He's gotten a 30' x 50' steel building for free. The tire place was going to put up a new building & were getting bids to tear down there old building, so they could put up a new larger one. He goes & tells them that he'll do it for free, but they need it down in a day, he tells them it will be down by Monday. Of course they said yes. So him, his brother & 3 sons go up there & unbolt this steel building & hauled it away in a weekend. They were done on Sunday. It took a couple of hundred dollars in gas, to haul it back to his place but he got the roof, frame, walls, electrical boxes & lights too. It's a nice shop now.

Old car engines & transmissions have lots of good nuts & bolts, shafts & gears. I have saved a couple of car struts & a pair of leaf springs. I salvaged an old rack mount computer console, it had some nice pieces of 1/4" Almuinum plate, lights, fans, switches, & wire.

Keep your eyes open, & sometimes you get lucky. I found a couple of huge bolts half buried on the side of the road when I stopped to fix a flat, the bolts where about 18 inches long & 2 inches in diameter, I have no idea what they would have went to, a bridge maybe. I've run across stuff put in the woods before, but never tried to salvage any of it. Old cars, ovens, Old farm equipment has literally tons of good material on it. I also found an old school wood stove that was a couple hundred pounds of cast iron.I've found some good hardware being thrown out during/after a building remodel near my house, light fixtures, a bunch of little bags of bolts & screws, a chunk of counter top, a couple of ceiling fans. I got them all for free buy talking to the owner when I was walking the dog. Put the ceiling fans in the garage with 3 100watt CFL bulbs in them, really added some light in there, plus the 3 of the 4 four light fixtures worked fine, put those in the attic so I can see what's stored up there better.

I've gone to auctions, a few times, & it's amazing what you'll find. The longer you stay the better deals you'll get. I've also seen people go nuts at auctions & pay more for used stuff than what the same item would cost new at the store. Same thing at flea markets, at the end of the day you get amazing deals, some people will give you stuff just so they don't have to haul it back home.

By far the best scrounger I've ever seen is my girlfriends retired father. He's gotten a 30' x 50' steel building for free. The tire place was going to put up a new building & were getting bids to tear down there old building, so they could put up a new larger one. He goes & tells them that he'll do it for free, but they need it down in a day, he tells them it will be down by Monday. Of course they said yes. So him, his brother & 3 sons go up there & unbolt this steel building & hauled it away in a weekend. They were done on Sunday. It took a couple of hundred dollars in gas, to haul it back to his place but he got the roof, frame, walls, electrical boxes & lights too. It's a nice shop now.

- Joined

- Jul 26, 2011

- Messages

- 4,142

Don't forget springs out of old ball point pens.

We had a 1950'5 or 60's 8" Delta woodworking jointer at work. It did not have jack screws for setting the knives at the same height. It was a pain to replace knives without jack screws. However,it did have a hole drilled near each end of the slots the knives sat in. Holes were for some manufacturing purpose,I guess. I figured out I could put small springs in each hole,so the knives would be pushed upwards against a stop while tightening the gib screws. It was a huge improvement in changing the knives.

Some years later I discovered Dispoz-a-Blades,which just sit in the bottoms of the grooves. We went to using them,which further solved all problems. We could change the thickness planer knives (the worst knife replacing job) in 15 minutes.

We had a 1950'5 or 60's 8" Delta woodworking jointer at work. It did not have jack screws for setting the knives at the same height. It was a pain to replace knives without jack screws. However,it did have a hole drilled near each end of the slots the knives sat in. Holes were for some manufacturing purpose,I guess. I figured out I could put small springs in each hole,so the knives would be pushed upwards against a stop while tightening the gib screws. It was a huge improvement in changing the knives.

Some years later I discovered Dispoz-a-Blades,which just sit in the bottoms of the grooves. We went to using them,which further solved all problems. We could change the thickness planer knives (the worst knife replacing job) in 15 minutes.

Cement nails

Cement nails are pretty good steel (tough and hold an edge). Seems to me that one could grind one into a mini boring tool for example.

It would be great to hear from someone who has tried making cutting tools from cement nails.

Cement nails are pretty good steel (tough and hold an edge). Seems to me that one could grind one into a mini boring tool for example.

It would be great to hear from someone who has tried making cutting tools from cement nails.

Last edited:

- Joined

- Dec 8, 2013

- Messages

- 2,651

Re: Ideas for Scroungers - More ideas

Don't throw away the disk drives out of those computers. They contain lots of lovely little precision parts and always have some rare-earth magnets. The motors can sometimes be salvaged. The older they are the better.

I've got two of those automated cat-crappers. The pump is usable as-is (as a coolant pump for your mill, for example). The motors (including the pump motor) are two-phase PM motors that can be used as 110V steppers. The pc board contains a general-purpose single-chip computer that can be reprogrammed and eight relays intended to control the motors and heaters.

Don't throw away the disk drives out of those computers. They contain lots of lovely little precision parts and always have some rare-earth magnets. The motors can sometimes be salvaged. The older they are the better.

I've got two of those automated cat-crappers. The pump is usable as-is (as a coolant pump for your mill, for example). The motors (including the pump motor) are two-phase PM motors that can be used as 110V steppers. The pc board contains a general-purpose single-chip computer that can be reprogrammed and eight relays intended to control the motors and heaters.

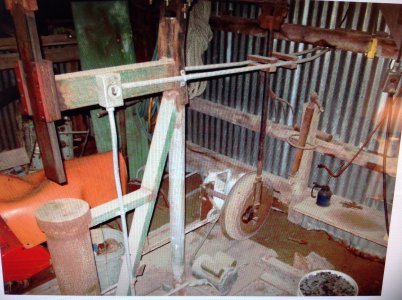

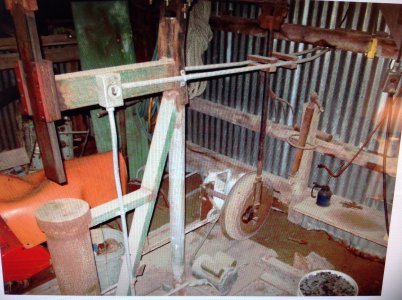

My family thinks I'm THE KING OF SCROUNGERS. I've got old sets of plows and cultivators and all kinds of "Junk" just sitting around in different places in my woods. I was looking for something to make a fairly large drive pulley out of, a while back, because I had seen on the internet where a blacksmith had built himself a power hammer. I had an old set of 2 bottom pull type plows parked many years ago. I studied them for a few minutes and pictured how I thought I could transform them. Attached is a picture of my hammer made mostly from those plows. The furrow wheel made a good drive pulley with some modifications. It was the perfect wheel in which to mount a flange mounted pillow block bearing just out of center to serve as a driver for a vertical shaft to go up and push and pull on a truck spring that causes the hammer to slam. Good thing I don't have close neighbors because this thing is a noise maker. Hearing protection is a must.

Jim Dunn

Harrington, Delaware

Jim Dunn

Harrington, Delaware

- Joined

- Feb 27, 2012

- Messages

- 45

Springs seem to be a hot topic, so I'll add an idea that we've used in our shop for years. To hold the parallels apart in a machine vise, to hold pieces of paper on a drawing board, to hold the jaws of a parallel clamp apart, and for so many other things, the black metal strapping that comes wrapped around heavy items on a pallet make the best darned "leaf" springs around. We have used them in so many places I can't recall them all. I bought an imported set of thin parallels, heavily discounted for no apparent reason. It was advertised to contain 20 pairs of thin (spring steel) parallels. Well, when it came in, I found out that it actually only contained 18 sets of parallels. The 3/8 and 7/16 sizes were missing. I happened to have some (several yards, as a matter of fact) spring steel strapping on hand, in 1/2", 3/4" and even 1" width (you need big, American-made tin-snips to cut that stuff), so I cut some pieces of the 1/2" stock to length and carefully ground them to width. I sandwiched the pieces between some cold-rolled junk steel I had laying around and put them diagonally on my grinder chuck. By minimizing the contact area and using a fairly coarse wheel, I got them down close to finished size, then switched to a fine wheel to get a smooth surface and finish the width. Now, I have the 20 pair set I wanted. BTW, 1/2" black strapping can be cut to length, drilled at both ends and bent at the ends to form a tab. Then it can be wrapped around round flexible duct tube on dust collectors and such and held together with a screw and nut. Also makes a great place to attach a ground wire to bleed off static electricity to help avoid dust explosions in a wood shop.

Completely off the idea of springs, we have a couple old flat-top school desks that came from a school auction, which make right-height benches for our belt sanders. The lift-top opens up to dump off the collected dust and grit and the inside compartment holds sander belts and such.

I also once salvaged some room dividers from a college bookstore reno project. They were custom made with large panels of safety glass, like in an automobile window, and steel channel framing. I got about 10 pieces of glass about 3' square and some lengths of steel channel. Since they were made in sets of 3 and 4 panels, the top and bottom channels were one piece, and the bottom channels had flat steel mounting brackets mounted crosswise every 18 inches or so. All in all, a good haul. From the same store reno project, I salvaged a dozen older 4-tube, 4-foot "troffer" type fluorescent fixtures, most of which worked fine, and they came with a whole box (about 24) of brand-new plastic, crackle-finish diffuser panels. Nearly 25 years later, some of those lights are still in operation. I also got a couple hundred square feet of slate floor tile. NEVER, I repeat, NEVER, EVER make an outside walkway out of slate tiles if you live in an area that gets snow, ice, or rain. These tiles became as slick as a greased slide when wet, probably due to the sealer that had been applied to them. We had to tear them up and move them to a less walked-on location. It took a couple years for the sealer to wear off and expose the original surface that was a lot less slippery when wet. I later found out that the reason they had been taken out was - you guessed it - they got real slippery when wet. The store was worried about liability issues.

Completely off the idea of springs, we have a couple old flat-top school desks that came from a school auction, which make right-height benches for our belt sanders. The lift-top opens up to dump off the collected dust and grit and the inside compartment holds sander belts and such.

I also once salvaged some room dividers from a college bookstore reno project. They were custom made with large panels of safety glass, like in an automobile window, and steel channel framing. I got about 10 pieces of glass about 3' square and some lengths of steel channel. Since they were made in sets of 3 and 4 panels, the top and bottom channels were one piece, and the bottom channels had flat steel mounting brackets mounted crosswise every 18 inches or so. All in all, a good haul. From the same store reno project, I salvaged a dozen older 4-tube, 4-foot "troffer" type fluorescent fixtures, most of which worked fine, and they came with a whole box (about 24) of brand-new plastic, crackle-finish diffuser panels. Nearly 25 years later, some of those lights are still in operation. I also got a couple hundred square feet of slate floor tile. NEVER, I repeat, NEVER, EVER make an outside walkway out of slate tiles if you live in an area that gets snow, ice, or rain. These tiles became as slick as a greased slide when wet, probably due to the sealer that had been applied to them. We had to tear them up and move them to a less walked-on location. It took a couple years for the sealer to wear off and expose the original surface that was a lot less slippery when wet. I later found out that the reason they had been taken out was - you guessed it - they got real slippery when wet. The store was worried about liability issues.