Did you get the X and Y feed handwheels?

No, I didn’t. The previous owner had it CNCed on the x axis but took the servos off when they quit using this mill. They left a small spur gear on the left end of the lead screw, to which I’ve been attaching a strap wrench to turn it. I’ve been able to use the knee crank on the Y axis, since it still has its crank collar.

I priced replacement parts from W-I and they were about what I expected - high. I purchased the two missing end plates for $73 each.

The hand wheels and associated pieces amounted to over $750 each, which I passed on.

Here’s what I’m doing. I bought these hand wheel castings from MSC:

And these handles:

I’ve somehow lost the photos of machining the hubs on the handwheels, but here’s how I did it. I was able to hold it from the inside with a three jaw chuck. I faced and turned the hub to the proper diameter, and bored the thru hole. I then turned them around and chucked on the hub to face the front side.

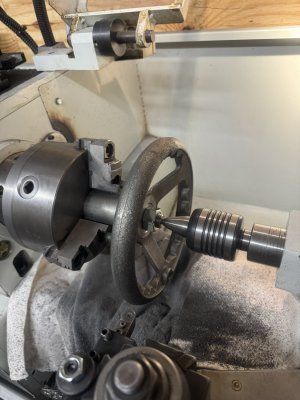

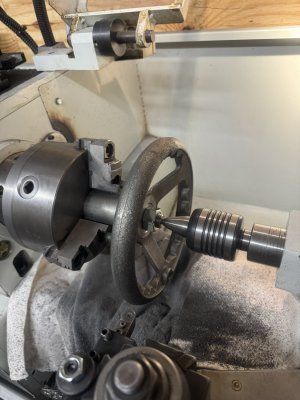

Next I made an arbor to hold the wheels for the remaining operations.

Holding this arbor in a super spacer, I drilled the holes for the roll pins on the hubs. Then I flipped them over and drilled and tapped the hole for the handles.

After installing the roll pins in the hubs, I put the arbor back in the lathe to turn the radius on the perimeter of the wheels.

I used a round cutting tool and approximated the 1/2” radius on the handwheels using the DRO on the lathe. I calculated the points using Microsoft Xcel and made a chart to reference while cutting. Here is the finish after turning.

Then using a succession of files, Emory paper, and Scotch Brite, I smoothed out the ridges and polished to a shine.

I then cleaned up the parting lines on the internal surfaces and spokes with a rotary bur prior to painting.

I just got them painted last night, and here is the final product.

I still need to make the collars for the x-axis screw that the handwheels engage. That’s the next order of business.