- Joined

- Jun 19, 2017

- Messages

- 83

Hello again,

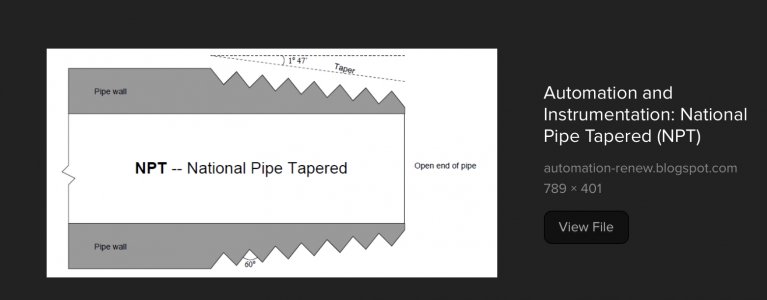

Recently I needed to drill and tap a bunch of 1/16 NPT ports in some steel plates.

As hard as I tighten my drill chuck, the tap goes in a few turns and then slips in the chuck.

I tried using a collet and had the same result.

I got the job done but I know I'll be doing more of these and hoping I can come up with a better way to hold my taps.

?? suggestions?

Oh, and my drill bits slip too. My chuck is 1/2" and is the one I bought from Precision Mathews when I bought the mill.

Jim

Recently I needed to drill and tap a bunch of 1/16 NPT ports in some steel plates.

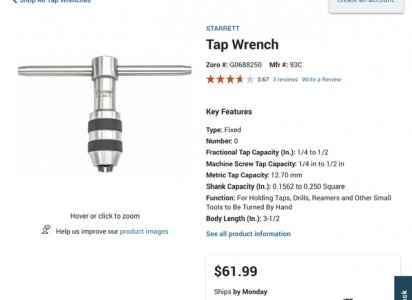

As hard as I tighten my drill chuck, the tap goes in a few turns and then slips in the chuck.

I tried using a collet and had the same result.

I got the job done but I know I'll be doing more of these and hoping I can come up with a better way to hold my taps.

?? suggestions?

Oh, and my drill bits slip too. My chuck is 1/2" and is the one I bought from Precision Mathews when I bought the mill.

Jim