- Joined

- Feb 8, 2014

- Messages

- 11,144

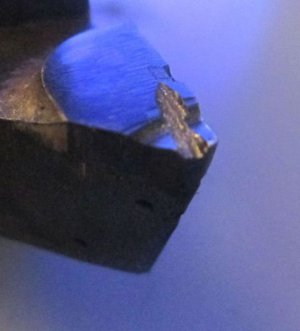

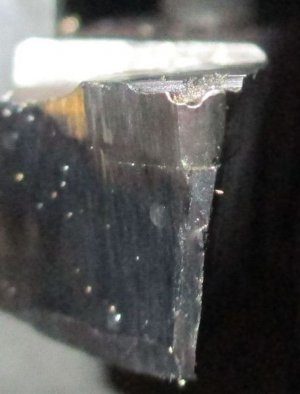

I am turning some 4150 and needed to grind a chip breaker into the cheap HF POS brazed carbide bit. I was heading for the carbide grinder and noticed I had a few Dremel 545 diamond wheels in the top of my tool box that I had bought for another project. I thought, hmmmm:thinking:. I grabbed the Dremel, chucked it up, and tried it, it cut carbide like butter. I was able to grind a nice chip breaker in the tool and do a bit of other shaping on the bit also. This is one of those things I never thought of before.

Just thought I would pass it along.

About $18 at Home Depot or buy online for less.

From Dremel's description: ''The 545 Diamond Wheel is completely coated with fine diamond particles for working with hard materials. Designed to be long lasting and not lose its shape or break, it provides smooth, fine cuts. Great for cutting, sawing and carving of hard materials, such as marble, concrete, brick, porcelain, ceramics, hard epoxy and soft and hard wood''

From Dremel's description: ''The 545 Diamond Wheel is completely coated with fine diamond particles for working with hard materials. Designed to be long lasting and not lose its shape or break, it provides smooth, fine cuts. Great for cutting, sawing and carving of hard materials, such as marble, concrete, brick, porcelain, ceramics, hard epoxy and soft and hard wood''

Just thought I would pass it along.

About $18 at Home Depot or buy online for less.

From Dremel's description: ''The 545 Diamond Wheel is completely coated with fine diamond particles for working with hard materials. Designed to be long lasting and not lose its shape or break, it provides smooth, fine cuts. Great for cutting, sawing and carving of hard materials, such as marble, concrete, brick, porcelain, ceramics, hard epoxy and soft and hard wood''

From Dremel's description: ''The 545 Diamond Wheel is completely coated with fine diamond particles for working with hard materials. Designed to be long lasting and not lose its shape or break, it provides smooth, fine cuts. Great for cutting, sawing and carving of hard materials, such as marble, concrete, brick, porcelain, ceramics, hard epoxy and soft and hard wood''