I do not have a manual for my exact machine.

I found the below verbiage in a manual that is for a unit similar to this one:

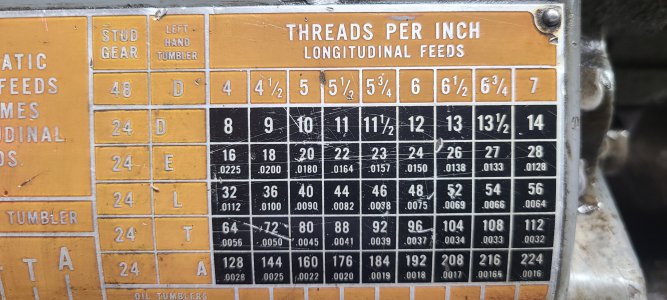

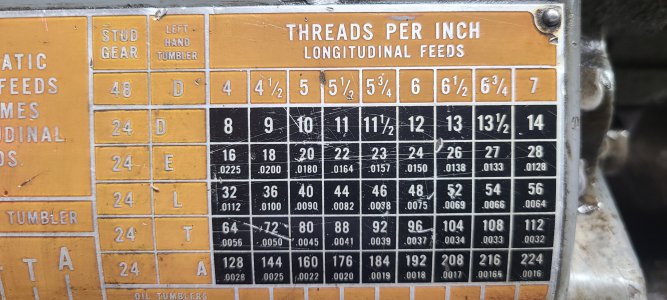

Fifty-four threads from 4 to 224 per inch can be cut by shifting the left and right tumbler levers and by changing one stud gear In the gear train. This is a gear type transmission which allows the operator to quickly select 54 different speeds of the Lead Screw. These speeds are really 54 different ratios relative to the speed of the spindle of the headstock. There are two input speeds of the gear box, obtained by exchanging the 24 tooth and 48 tooth stud gears mentioned above. The 48 tooth stud gear should be used only for chasing threads 4 through 7 pitch. The 24 tooth stud gear should be used for all other threads and for all power feeding. If this rule is violated, the thread and feed chart on the Quick Change Gear Box will not give correct readings. With the Quick Change Gear Box set for any of the eighteen (18) thread pitches from 4 through 14, the power feeds which could then theoretically be used, are too fast for all practical purposes. Therefore, in practice, the 48 tooth stud gear should not be used for power feeding, and the power feeds are not shown on the top two rows of the chart where threads 4 through 14 are indicated.

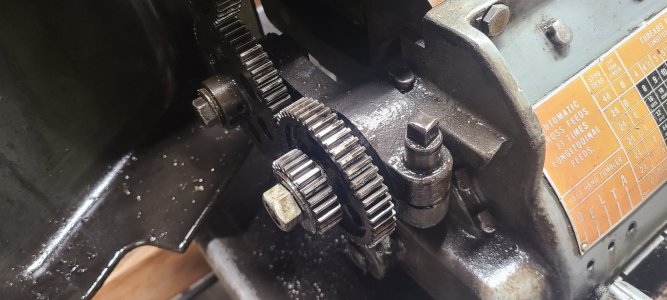

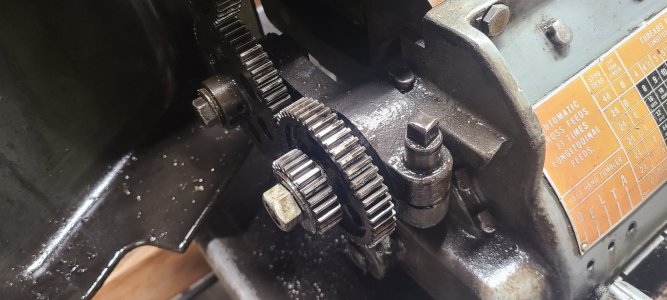

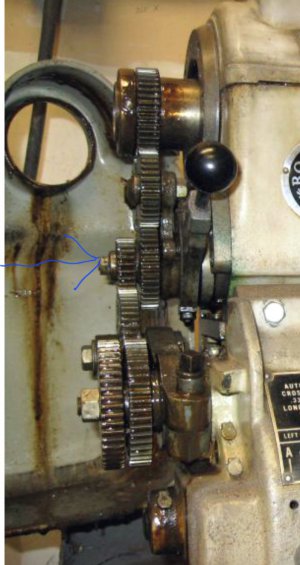

The gears in the picture above are the ones that drive the feed screw. There is a 48 and 24 tooth gear that are stacked on top of each other. I did not see another place to put those gears but I will look tomorrow morning when I can get back to the lathe. The machine came in the configuration shown. I swapped the gear and adjusted the idler to make them engage and it made it go to 7tpi with the 24T in use.

Due to the adjustable idler gear (the one in back in the photo) and the arm it rides on being able to accomodate either diameter of gear, I thought it looked like that was the swapping place. The idler gear is slid along the idler arm by loosening the nut on the face of the gear. The idler shaft is pivoted to attain proper backlash by loosening the square pinch bolt in the foreground of the pic. The gears are both splined to drive a shaft and I assumed....

There are many more gears above the three shown, so maybe it goes somewhere else. What piper184 says makes sense because if there is a bigger drive gear up higher, making it smaller would reduce the driven gear speed, which is what I think I need.

I know these old lathes are all different and I really appreciate your efforts in helping with this dilemma. Given my less than adequate descriptions, it is an even bigger challenge, so thank you.