- Joined

- Dec 10, 2023

- Messages

- 76

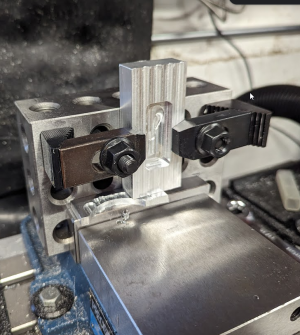

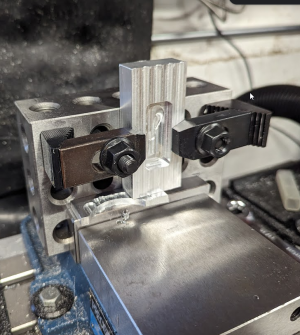

I went with the 246 block clamped into the vise. Then the part held to the 246 block with strap clamps. The extra rigidity on the Z axis of the part was what i was needed for this aluminum part and a drilling operations. Sacrificial piece under part so my drill did not make a new hole in my vise. I was able to used the edge finder on the part as i had some stick up on the part.

I cut the reamer to length. Then after all of the talk of cutting the reamer i got the idea to first measure the run out on the reamer and it was .005. That is what i get for buying used, but i had a smaller used reamer .502 that had .002 runout and used it. Glad i checked it!

Mock up picture (the part is not the real one).

The double vise idea i need to test to see if my 4" vise can hold it. Gotta keep that in my back pocket for sure.

All of the ideas were awesome! I will try to remember them when i run into a situation like this in the future.

I cut the reamer to length. Then after all of the talk of cutting the reamer i got the idea to first measure the run out on the reamer and it was .005. That is what i get for buying used, but i had a smaller used reamer .502 that had .002 runout and used it. Glad i checked it!

Mock up picture (the part is not the real one).

The double vise idea i need to test to see if my 4" vise can hold it. Gotta keep that in my back pocket for sure.

All of the ideas were awesome! I will try to remember them when i run into a situation like this in the future.