@Rex Walters thanks so much for taking the time! Much appreciated.

I spent a lot of time throwing ideas about myself and came up with this:

File surfaces 1 and 5 flat. Use them to bank on the fixed jaw with the tail hanging over the top. Mill 7 and 4. Drill and ream 2 x 8mm holes 25mm apart. Flip part, bank on previously milled surfaces and mill 3 and 8:

Place 2 pieces of 8mm silver steel in holes, rest on parallels:

This method made it easy to pick up the dowls and edge of the part with an edge finder to get the main bore dead nuts on.

Drill and ream 8mm to be used as alignment in the lathe:

Mill some scrap ali square and drill and ream holes to match the ones in the part:

The bottoms get drilled to clamp the the face plate:

Alingment in the lathe was easy. Leave the bolts just shy of snug, put an 8mm dowl pin the the chuck to pick up the hole started on the mill, spin it by hand to settle everything and snug it down. Indicated within tenths!

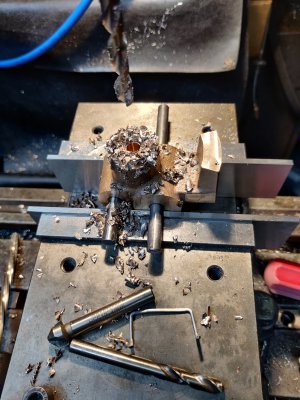

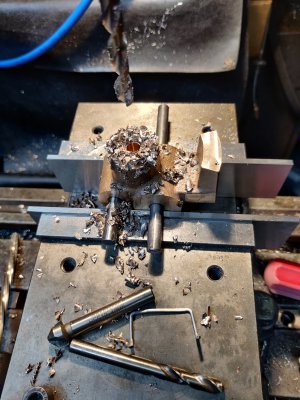

Machine in a suprisingly solid setup:

Check fit and adjust the mating part to suit:

Done!

Yes, there is an apprentice mark of shame. I was careless during one of the very first ops! Happily, I have designs on popping it in the rotary table to do some aestetic work on the dial, so that'll disappear anyway. Really looking forward to getting it on the RT!

I should mention that I'll be going the split cotter route, rather the split collar. It suited me to leave the clamp hole 8mm, and will continue to do so until I've done the rotary table work. I can easily pick it back up to open out for the cotters later and the resulting hole need not be crazy precise.

Thanks to everyone for chiming in. There's my solution, for what it's worth! I'm very happy with the result, the fit and aligment are spot on. Onwards!

www.hobby-machinist.com

www.hobby-machinist.com