I need help wiring my shaper. Previous owner(s) cut and removed the contactor.

Here is what I have, a 16" G & E shaper with a 5hp 3-phase motor.

On the machine there is a momentary type push button on/off switch, the wiring appears to be in the main housing with the oil and gears (but I cannot see or get to where the wire enters the switch to replace it).

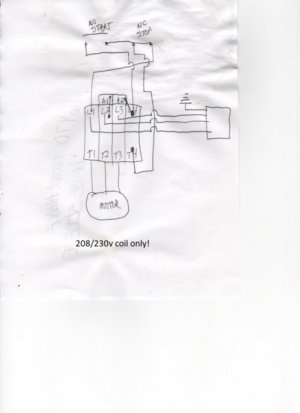

There is a Main Disconnect with 3-cartridge fuses (one for each phase), I have acquired a "newer" if not NOS contactor (or is this called a starter?) GE CL45

The push button switch on the shaper has 4-lugs, 1,2 &3 were used with #4 empty.

Photos of the parts are attached, what voltage is going to the switch? Normally, I wouldn't worry about it but the wiring exposed to the lube oil is a concern and I would prefer a low voltage on/off if possible. At this point I don't have a clue if the motor works, but it is a cool old motor and would like to keep it.

thanks,

Mike

View attachment 237834

View attachment 237834

Here is what I have, a 16" G & E shaper with a 5hp 3-phase motor.

On the machine there is a momentary type push button on/off switch, the wiring appears to be in the main housing with the oil and gears (but I cannot see or get to where the wire enters the switch to replace it).

There is a Main Disconnect with 3-cartridge fuses (one for each phase), I have acquired a "newer" if not NOS contactor (or is this called a starter?) GE CL45

The push button switch on the shaper has 4-lugs, 1,2 &3 were used with #4 empty.

Photos of the parts are attached, what voltage is going to the switch? Normally, I wouldn't worry about it but the wiring exposed to the lube oil is a concern and I would prefer a low voltage on/off if possible. At this point I don't have a clue if the motor works, but it is a cool old motor and would like to keep it.

thanks,

Mike

View attachment 237834

View attachment 237834

Last edited: