Hi Randy

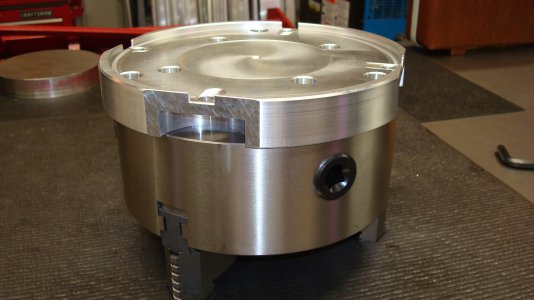

There is somthing to be said about bigger is better. Depending on what type of work your doing, getting things clamped down on the table can be a challenge. Those hold down kits that allmost every guy has for clamping things on the mill are commonly used. Small tables will be restrictive in that sense. Some times Ive used the 14 inch face plate on top of the R/T just to get a few more inches of table top, and If I need to drill and tap some holes on the face plate, I dont mind.

Adding a plate has some advantages. When your fitting a plate to your new R/T, you can allso use the dividing plates to put a series of holes in the plate, much like the dividing plate itself. Now you choose what sizes to tap them, and you have muliple spots for fasteners to hold your work down.

When looking for a new R/T, you will notice that depending on brand, and size, the table has 4 or 6 slots for T-nuts. This to me is a major concideration. AFAIK the 6-slot table makes life much easyer when mount work to your table. If in the event the table of the size you choose had only 4-slots, I would be mounting a plate to the table without a second thought. Even with a 6-sloted table, Ive had times when Im trying to mount a work piece down, and said to myself, damn, if there was only a drilled and tapped hole, right there! These are times when your going to wish you had the plate, lol.

You probably will want a table with a M/T centre. You will be suprized how many little adapters for things you will make. The extra T-slots also come in handy when mounting large objects with over hang. At first, you will be wondering just what to do with this new toy, but after some thinking outside the box, you will be constantly making up accesories to do jobs with your R/T. These are a very versatile tool, and it will test your imagination as to work holding abilitys. Ive had days when Im running out of ways to clamp things down, other days its just take one of my many vices and drop it on and go.

Will you regret getting the 8-inch? Well thats somthing that will really depend on your type of work. You will allways have the option of adding a plate to the excisting table. I like em big, but will admit,big can be a real pain at times. Personally, the 8-with a plate would do for most jobs.

I think the larger R/T are more robust.,thats why I got the 12-inch.

Size matters, some days!

Just my thoughts

Paul