- Joined

- Jul 16, 2013

- Messages

- 43

I saw a wire clamp tool made by clamptool.com the other day and thought it should be easy enough to make for home use.

The pictures should be self explanatory so here goes ..

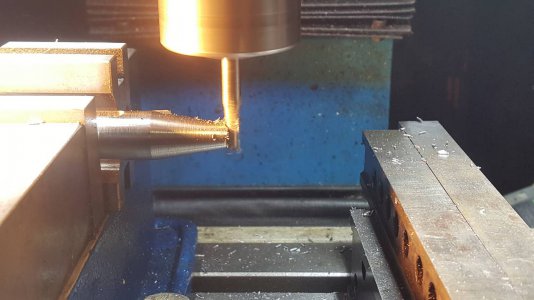

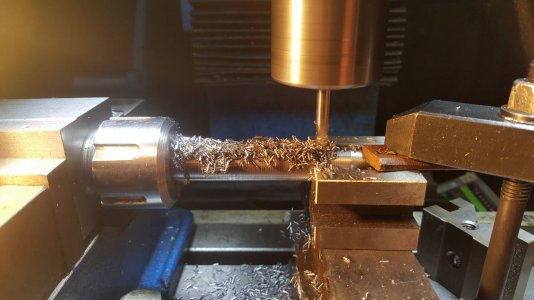

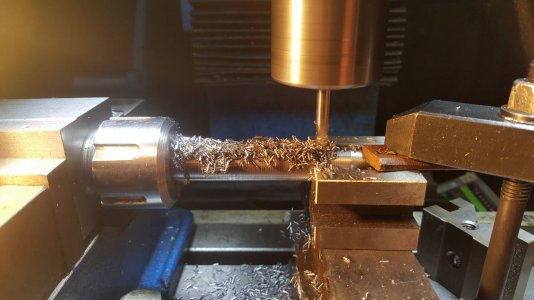

I like to use some paper tightly wrapped around the finished bit to protect against the jaws and it works quite well for me. I parted and then cut the taper

The rear parting tool still works like a charm

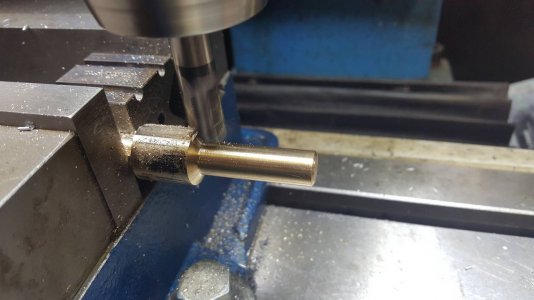

The finished taper

Lined it up in the mill to cut the slots

Slot almost done

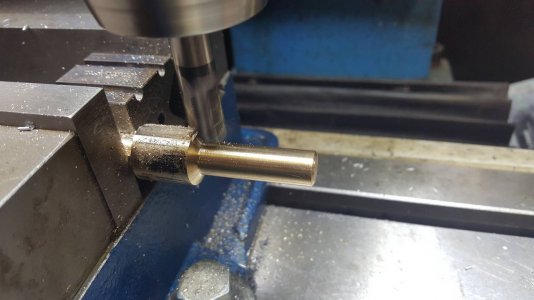

I used some brass to make the turn handle.

Milled a flat on the one side to thread

Drilled and tapped the handle

There after I case hardened the tip and drilled a 4.5mm hole in the threaded rod and installed a roll pin then assemble

Some notes: I opted not to install the front pin as per the original and I can say that it makes a difference after testing it. I made the tip to wide and will make a thinner tip for smaller/thinner wire clams.

All and all a fun and useful project to do.

Regards

Paul

The pictures should be self explanatory so here goes ..

I like to use some paper tightly wrapped around the finished bit to protect against the jaws and it works quite well for me. I parted and then cut the taper

The rear parting tool still works like a charm

The finished taper

Lined it up in the mill to cut the slots

Slot almost done

I used some brass to make the turn handle.

Milled a flat on the one side to thread

Drilled and tapped the handle

There after I case hardened the tip and drilled a 4.5mm hole in the threaded rod and installed a roll pin then assemble

Some notes: I opted not to install the front pin as per the original and I can say that it makes a difference after testing it. I made the tip to wide and will make a thinner tip for smaller/thinner wire clams.

All and all a fun and useful project to do.

Regards

Paul