How do I fix or what should I be looking for when my Atlas 618 back gear (the larger headstock gear) is separating from the v-belt pulleys and therefore the headstock stops spinning?

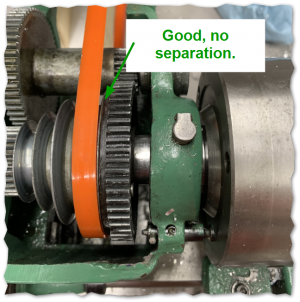

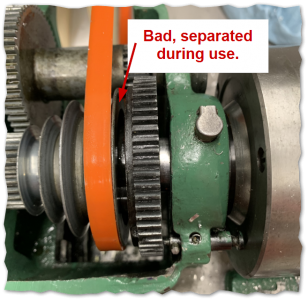

I attached two pics... a good and a bad, it goes from good to bad during use... I can slide it back, but it just keeps separating from the pulleys.

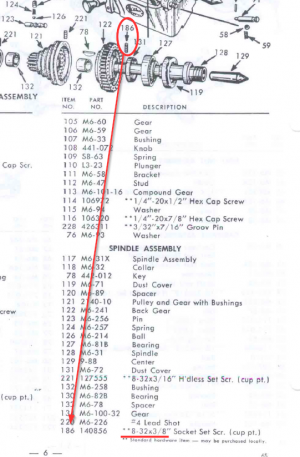

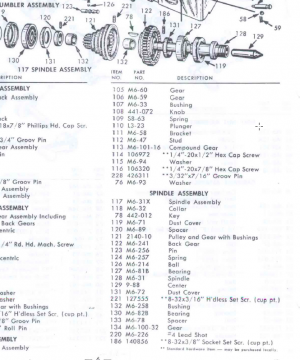

There appears to be two set screws in this larger gear, one over the pin that is pulled when you engage the back gear and one other. I think I'm missing the second one, I'll have to figure what the the size and thread is and source that. Not sure when I lost it. The one over the pin for the back gear engagement has a spring under it... so I imagine that it's not intended to be tightened down and possibly just put tension on the pin to keep it in place.

I just swapped out my standard 1725 RPM constant speed motor for a Consew CSM1000 variable speed motor, mended a new urethane v-belt and then started noticing the larger toothed gear in my headstock was separating from my v-belt pulleys in the headstock... I don't believe these changes are related but just coincidental.

Any thoughts/suggestion would be helpful!

Off topic... I did read the pinned thread on the set screw (or rather, it's not a set screw) on the v-pulleys, mine is in the bottom part of the second smallest v-pulley... I guess that and oiler area, looked like a set screw! Still learning the ins-outs of this thing and want to make sure I'm using and maintaining it properly.

I attached two pics... a good and a bad, it goes from good to bad during use... I can slide it back, but it just keeps separating from the pulleys.

There appears to be two set screws in this larger gear, one over the pin that is pulled when you engage the back gear and one other. I think I'm missing the second one, I'll have to figure what the the size and thread is and source that. Not sure when I lost it. The one over the pin for the back gear engagement has a spring under it... so I imagine that it's not intended to be tightened down and possibly just put tension on the pin to keep it in place.

I just swapped out my standard 1725 RPM constant speed motor for a Consew CSM1000 variable speed motor, mended a new urethane v-belt and then started noticing the larger toothed gear in my headstock was separating from my v-belt pulleys in the headstock... I don't believe these changes are related but just coincidental.

Any thoughts/suggestion would be helpful!

Off topic... I did read the pinned thread on the set screw (or rather, it's not a set screw) on the v-pulleys, mine is in the bottom part of the second smallest v-pulley... I guess that and oiler area, looked like a set screw! Still learning the ins-outs of this thing and want to make sure I'm using and maintaining it properly.