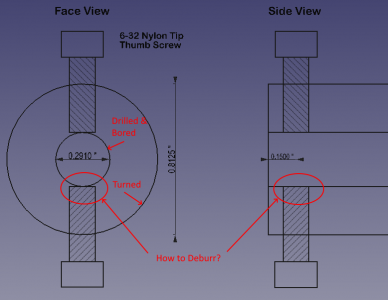

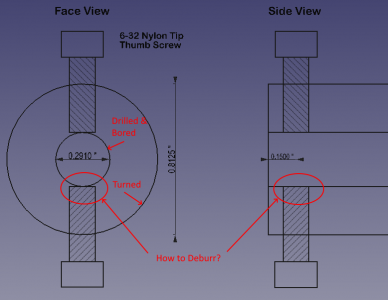

I've turned, drilled and bored a part as shown below by first drilling and tapping the two cross holes, then turning the outside, then drilling and boring the inside. I did it that way because I couldn't figure out how to deburr the cross holes inside the bore if I turned and bored first. For the most part the bore is burr-free but, I think I could get a better quality bore if the tool didn't have to play whack-a-hole with the cross holes, same for the outside turn. Any ideas?

Thanks.

Thanks.