-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How fast is too fast?

- Thread starter Reddinr

- Start date

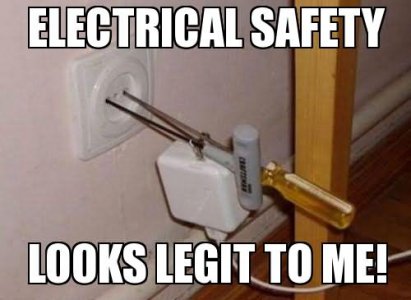

What could possibly go wrong???

That question can be asked jokingly, carelessly, or seriously.

That question can be asked jokingly, carelessly, or seriously.

What could possibly go wrong???

And for whom?

Machines get sold, sometimes by spouses or relatives. Another good reason for the next buyer to do all his math before putting on a chuck and powering the machine.

-frank

Safety third ....................

When it comes to lathes; the limitations start with what is attached to the spindle. Jawed chucks have cast iron or semi-steel bodies. Cast iron is definitely lower RPM being of lower molecular integrity. They may have balancing performed at the factory but not outside a limited speed range. Another issue for jawed chucks are those with self centering; the scroll subject to inertia beyond a rated RPM, and SFPM for it's size.

Don't overrun tooling. Machines too are restricted by design and weight bearing components; chiefly at the spindle where factory 'X' cannot control what a user attaches. Like why your little Clausing hasn't a D1-6 spindle, or my Pacemaker a D1-8.

My favorite appraisal of lathe design rigidity is length of headstock, representing distance between main bearings. IMNSHO a good ratio is 3-4 times swing for heavy duty and real nice toolroom, about 1.5-2.0 for an average engine lathe.

Don't overrun tooling. Machines too are restricted by design and weight bearing components; chiefly at the spindle where factory 'X' cannot control what a user attaches. Like why your little Clausing hasn't a D1-6 spindle, or my Pacemaker a D1-8.

My favorite appraisal of lathe design rigidity is length of headstock, representing distance between main bearings. IMNSHO a good ratio is 3-4 times swing for heavy duty and real nice toolroom, about 1.5-2.0 for an average engine lathe.

Thanks for all the valuable input. I enjoyed the over-the-top use of an excavator on the lift. Someone actually did that??

In my case, I'm pretty level headed and not felony stupid (just normal stupid sometimes). If I was that dumb, I wouldn't have asked the question in the first place and would have just cranked the thing up to max and "give her a go" with predictable results. I learned a bit about my chucks' ratings so that will be some guidance. Great point about the potential next owner. If I do anything, I can set the upper limits of the VFD temporarily and then back to the normal 1800 RPM limit.

I believe that this lathe was not designed so that at 1801 RPM things start flying apart, especially with a small chuck/part mounted. The trick is "staying well inside that envelope" and not pushing it. I think centrifugal force increases with RPM^2 so a 10% RPM increase is about 20% more force. So, if I do anything at all, after considering it, I'll likely keep it to at most 110% of nameplate.

In my case, I'm pretty level headed and not felony stupid (just normal stupid sometimes). If I was that dumb, I wouldn't have asked the question in the first place and would have just cranked the thing up to max and "give her a go" with predictable results. I learned a bit about my chucks' ratings so that will be some guidance. Great point about the potential next owner. If I do anything, I can set the upper limits of the VFD temporarily and then back to the normal 1800 RPM limit.

I believe that this lathe was not designed so that at 1801 RPM things start flying apart, especially with a small chuck/part mounted. The trick is "staying well inside that envelope" and not pushing it. I think centrifugal force increases with RPM^2 so a 10% RPM increase is about 20% more force. So, if I do anything at all, after considering it, I'll likely keep it to at most 110% of nameplate.