- Joined

- Jun 26, 2018

- Messages

- 1,733

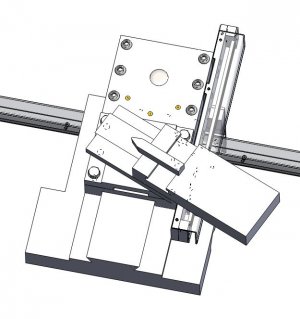

I have done many mods too. 6 bolt compound clamp, VFD- I can go down to 8 rpm and if I wanted to die, +4000 rpm, electronic lead screw (no more change gears). Switched the tapered spindle bearings to Nachi. A bunch of small things as well. My only wish, it were heavier/more rigid. That's not so much a G0602 problem, more so a small lathe issue. I bought it when Grizzly sold for $1800 but I got the G0602z (I think 2K for DRO "Z" version.)