Spark test. You will have no problem distinguishing medium carbon from mild steel. Difference between grades 5 and 8 will be harder. Maybe a file or test? The late, great guru of anvilfire.com cautions against depending too much on the extra strength provided by grade 8 over grade 5. I bought a box of mystery drill bits. Some were simple carbon steel. They were impossible to keep sharp. Ended up retiring all of them (that doesn't mean throwing them away).

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

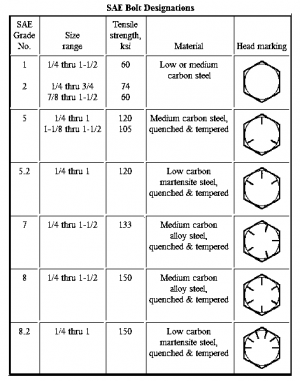

How do I test unknown bolts?

- Thread starter Batmanacw

- Start date

I already know which bolts are grade 2, 5, and 8. I wanted to know if they are up to nominal specs.Spark test. You will have no problem distinguishing medium carbon from mild steel. Difference between grades 5 and 8 will be harder. Maybe a file or test? The late, great guru of anvilfire.com cautions against depending too much on the extra strength provided by grade 8 over grade 5. I bought a box of mystery drill bits. Some were simple carbon steel. They were impossible to keep sharp. Ended up retiring all of them (that doesn't mean throwing them away).

The grade 2 made it to almost double the rated torque specs. 35 to 40 ft lbs. I'm not dissatisfied. They are rated for 20 ft lbs lubricated.

- Joined

- Feb 1, 2015

- Messages

- 9,645

Bolt torque failure isn't a good indication of bolt strength. Torque specs for fasteners are intended to provide guidance as to the maximum amount of torque that can safely be used without damaging the fastener threads.

It did show a clear difference between grades.Bolt torque failure isn't a good indication of bolt strength. Torque specs for fasteners are intended to provide guidance as to the maximum amount of torque that can safely be used without damaging the fastener threads.

Torque to failure may not be a 'good' indication of bolt tensile strength but surely both values would always increase together? Would be really interested to know where that relationship does not apply to the world of common fasteners.Bolt torque failure isn't a good indication of bolt strength. Torque specs for fasteners are intended to provide guidance as to the maximum amount of torque that can safely be used without damaging the fastener threads.

Cheers

Clint

- Joined

- Jan 2, 2019

- Messages

- 6,587

I hope you didn't take offense. Use them as you will but keep in mind the next person who comes across them may not be as diligent as you are.I'm not in the marine industry. These are not completely unknown or damaged.

This is my favorite reference book on the subject:

Cheers,

John

- Joined

- Jun 11, 2022

- Messages

- 16

Lots of good info here. But let me add a few important ones.

Testing to failure is a great way to test the final strength of a bolt. But then the bolt has been ruined.

Testing a sample of Bolts to failure is not a valid test unless all the Bolts and their histories are identical. Yours are not.

Therefore testing to failure isn't very useful.

You can certainly test to recommended torque for that size and grade. This won't have any affect on a good bolt. However, this does not in any way evaluate the strength of the bolt. Recommended torque is the torque required to hold a bolt in the fastened state under load. It is not intended to permanently deform the threads. Design torque maintains the stresses well inside the elastic range - well below the point where they deform or stretch permanently.

My advice is to use them as is. If they take their design torque they will likely be just fine. The only exception would be bolts that have started to fail in fatigue. But there is no way to test for that in a home shop. For mission critical applications, go get new bolts.

Testing to failure is a great way to test the final strength of a bolt. But then the bolt has been ruined.

Testing a sample of Bolts to failure is not a valid test unless all the Bolts and their histories are identical. Yours are not.

Therefore testing to failure isn't very useful.

You can certainly test to recommended torque for that size and grade. This won't have any affect on a good bolt. However, this does not in any way evaluate the strength of the bolt. Recommended torque is the torque required to hold a bolt in the fastened state under load. It is not intended to permanently deform the threads. Design torque maintains the stresses well inside the elastic range - well below the point where they deform or stretch permanently.

My advice is to use them as is. If they take their design torque they will likely be just fine. The only exception would be bolts that have started to fail in fatigue. But there is no way to test for that in a home shop. For mission critical applications, go get new bolts.

Last edited: