A lot depends on what you are measuring. Also what you are mounting the indicator on; workbench, surface plate, lathe, mill, etc.

There are 100’s of different ways to mount indicators. None of them are wrong. Some are just easier to set up. Others are more rigid. The “right way” to do it is the way that works for you.

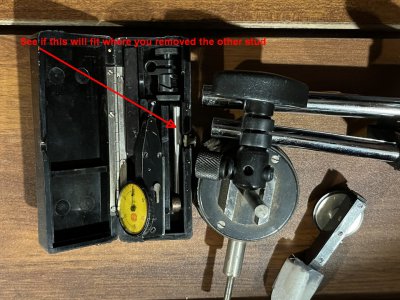

You don’t always have to use the mag base. Most who use indicators are machinists. All of the machinists I have worked with have fabricated their own adapters to do what they need to do.

The more you use your indicators, the more you will see the short comings of the as supplied adapters.